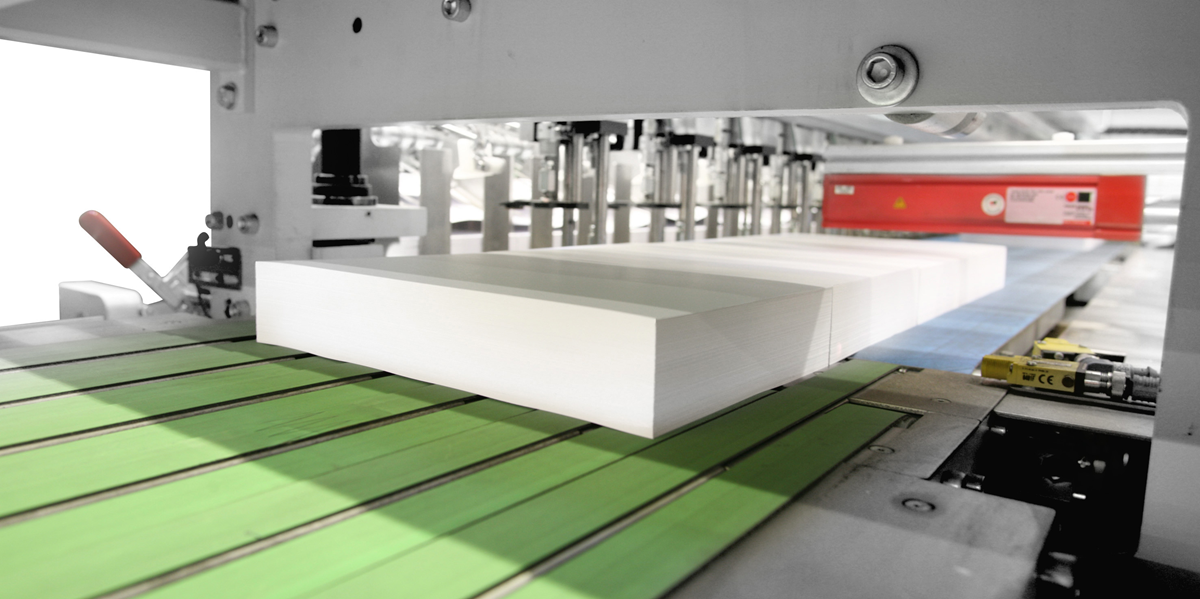

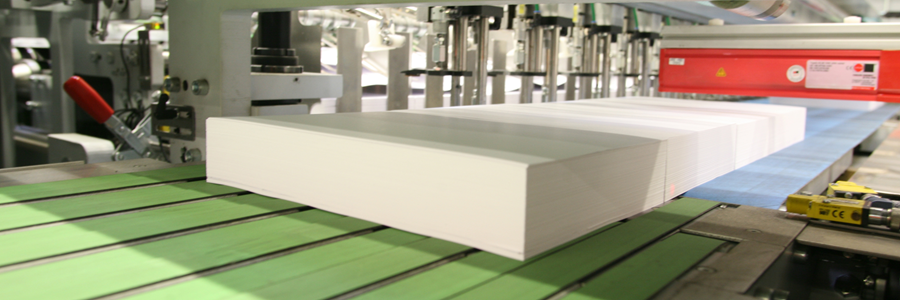

SLK 490 High-Performance Cut-Size Sheeter

Product Description

Mass production of all common paper grades with perfect ream and cut quality

Available with 7 up to 10 pockets, the SLK 490 series sets standards in mass converting of all common paper grades. It offers high-performance with speeds of up to 450 m/min, at maximum cost-effectiveness. At all speeds, compliance with the strictest quality standards (ream quality, sheet squareness, cut accuracy and cut quality) is guaranteed.

- High speed production of up to 180 reams per minute

- Excellent cut quality that fulfills all standards worldwide

- Non-stop reel change, special unwind design for efficiency and partial to full automation

- Variation in number of reams directed to left or right discharge during production

- Movable operation terminal with touch screen

- Sliding acoustic guards, low noise level

- Easily accessible design reduces changeover times & maintenance downtimes

- Efficient order handling through Manufacturing Execution System (MES)

- Paper mills and large paper converters

Product Features

The cut-size sheeter SLK 490 sets standards in mass converting of all common paper grades. Available with 7 up to 10 pockets, it offers high-performance with speeds of up to 450 m/min. With maximum cost-effectiveness, it provides the perfect ream and cut quality.

High Performance

Excellent Cut Quality & Precision

Automation & Manufacturing Execution System (MES)

Trouble-free Production

| Working Width (max.) | 1800 mm (8 / (7) pockets) 2160 mm (10 / (9) pockets) |

| Pockets | 8 (7) to 10 (9) |

| Reel width (min.) | 700 mm |

| Reel width (max.) | 1825 - 2235 mm |

| Reel diameter (Standard) | 1600 mm |

| Ream height (max.) | 130 mm |

| Output (reams per min.) -Single discharge- | 144 - 150 reams |

| Output (reams per min.) -Dual discharge- | 144 - 180 reams |

| Speed (max.) | 450 m/min. |

| Working strokes | 18 |

| Size width | 180 mm (min.) |

| Size length | 210 mm (min.) 457,2 mm (max.) |

| Cutting tolerance | +/- 0,2 mm |

| Cross cutter knife load (max.) | 600 gsm |

A benchmark in high productive cut-size sheeting

Mass production meets flexibility

The SLK 490 series sets standards in mass converting of all common paper grades. Available with 7 up to 10 pockets, it can discharge 180 reams per minute at a speed of up to 450 m/min and its maximum working width of 2160 mm with 10 adjacent pockets. A high degree of automation maximizes productivity. Flexible size change features and an easily accessible machine design guarantee efficient and simple operation.

Excellent cut quality and precision

Like all cut-size sheeters from WillPemcoBielomatik, also the SLK 490 guarantees excellent cut and ream quality. A precision cross cutter with advanced knife technology ensures that all quality standards (angle accuracy, cutting tolerance and cut quality) are fulfilled.

Optimal configuration for increased productivity

An optional dual discharge, enabling the number of reams directed left and right to be varied during production, provides you with a unique production advantage in the competitive paper converting market. Compatible, fully automated WillPemcoBielomatik packaging systems complement the high productivity of your line.

Automation & Manufacturing Execution System (MES)

The high level of automation includes automatic reel change. Our specially developed Manufacturing Execution System (MES) guarantees flexible and efficient production by controlling and monitoring the entire production process – for orders starting at one pallet.

Simple operation saves time

System solutions for cut-size sheeter SLK 490

This high-performance sheeter can be integrated with

- WillPemcoBielomatik inline packaging systems

- Ream wrapper

- Ream labeler

- Ream inspection / rejection

- Ream stacker / accumulator

- Case packer

- Case labeler

- Case inspection / rejection

- Interfaces for integrating palletizers & pallet packaging

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

a2a25e0f-43cd-43f0-9c3f-a5cc11fbcc29.jpg?sfvrsn=4dd9e7f_1)

359d5a13-484b-4d53-ac6f-d25f42158726.jpg?sfvrsn=c8dd9e7f_1)

.jpg?sfvrsn=a0dd9e7f_1)