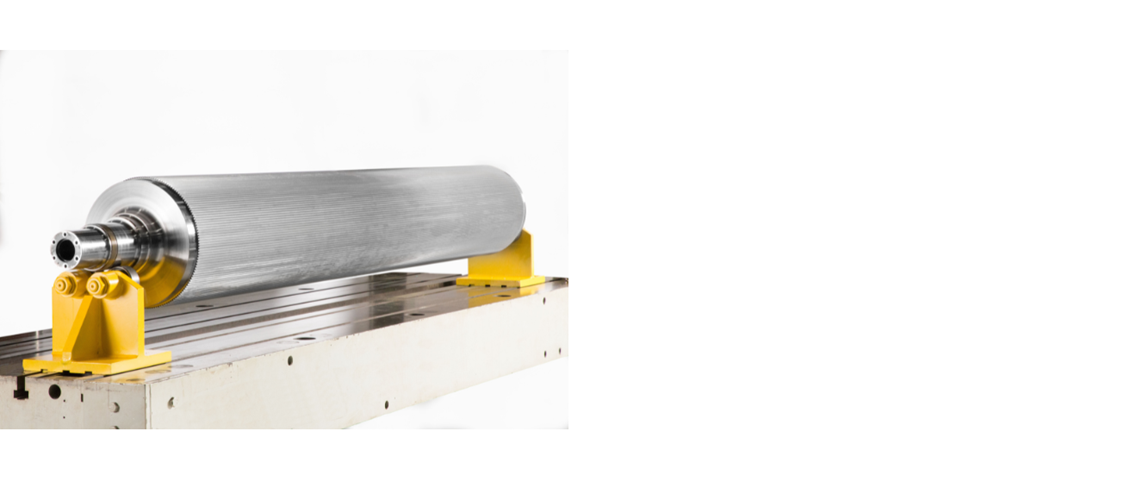

Corrugating Rolls

Description

BW Papersystems supplies new corrugating rolls for any singlefacer. Existing rolls can also be reground. The rolls are profile ground to extreme accuracy on world-class machines located in Phillips, WI.

Applications

New rolls are available for any brand or model Singlefacer

- Koppers

- Langston

- fosber

- Bobst/Asitrade

- MHI

- BHS

Benefits

- Precision regrinds minimize diameter reduction, extending roll life by allowing additional regrinds

- Paper saving low take-up profiles are available, including custom flute profiles (YouFlute) to optimize board properties and minimize paper consumption

- ASME certification and engineered procedures for leak, journal, and flute repairs

- New or rebuilt carts and modules are available

- Module exchange programs deliver savings on installation cost and time

- Industry leading delivery available

- Engineered Gundrilled roll solutions

- Installation packages with pressure roll and glue rolls Coating Options

- Duroclad is the industry leading coating, with multiple examples recorded in excess of 1 Billion lineal feet of production

Roll Services

New or Rebuild Glue Rolls

- Satin or engraved roll finishes

- Bearing/assembly packages available for easy installation

- Weld/journal repair upon inspection

New or Rebuild Metering Rolls

- Multiple cell volume options available for specific applications

- Bearing/assembly packages available for easy installation • Weld/journal repair upon inspection

New or Rebuild Pressure Rolls

- OEM drawings available for United/Koppers/Langston

- Bearing/retainer/assembly with grease-packed bearing packages available for easy

Installation

- Weld/grind/journal repair options

- Available for any brand or model Singlefacer

- Vanguard pressure roll exchange program

Cart and Module Swap Program

- Re-manufactured roll module program pre-assembled with corrugating rolls installed and paralleled

- Reduces on-site installation from days to hours- only gaps need to be verified

- Vanguard roll/modules aligned on OEM factory alignment jigs

- Available for Vanguard/Advantage/Langston/BHS

Technical Services Available

- Installation service available to ensure reliable machine operation

- Process service available to enhance machine speed and board quality

- Worldwide technical resources are available 24/7

BW Papersystems also offers upgrades to your BW Papersystems Singlefacer or Glue Machine to increase machine performance and reliability.

- Controls upgrades to current industry standards

- DC to AC motor conversions

- Main Vanguard gearbox replacement package

- Speed increase

REQUEST A QUOTE

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)