Folding Carton Production

Folio Sheeters and Web-Fed Equipment for the folding carton industry and board mills

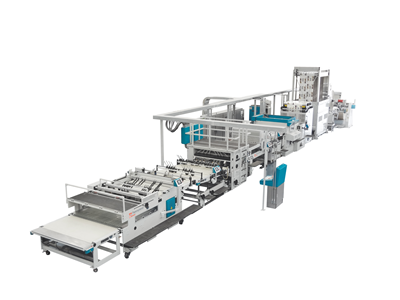

With its folio-size sheeters and web-fed platen die-cutters, BW Papersystems offers solutions for folding carton producers, board mills, paper and board converters.

No matter if web-fed or sheet-fed process - our machines provide the needed performance and product quality for any folding carton operation..

Folio-size sheeters from BW Papersystems are designed to handle a variety of large-size sheets at high-speeds to meet your production goals. With inhouse sheeting, you can flexibly cut to size as and when needed, saving money by buying reels and reducing storage süace. Customization options include levels of automation, splicing, automatic positioning slitters, edge guides, programmable decurling, tab insertes and much more.

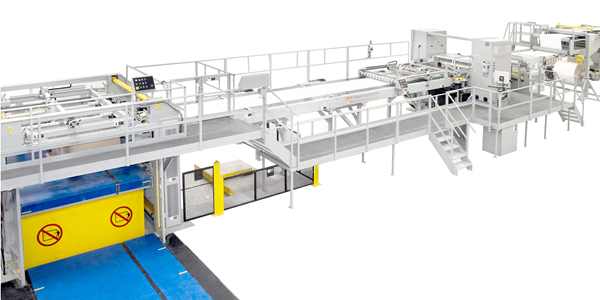

Zerand web-fed platen die cutter lines are the most efficient way to to produce a folding carton in a Roll to Blank to Stack process. This reduces plant storage and logistics, as there are less independent operations and movement of full pallets around the plant. The platen die cutters offers highest productivity and a reduced board usage with nesting layouts and no gripper margins. They also reduce operation steps and operators needed by more than 50%, as well as WIP and floorspace requirement. With web-fed platen die cutting, you can save by buying reels not sheets and eliminate sheeting or pile turning.

Web-fed Platen Die Cutters - 1400 (55 in)

Zerand web-fed platen die cutter lines are the most efficient way to to produce a folding carton. The platen die cutters offers highest productivity and a reduced board usage with nesting layouts and no gripper margins. They also reduce operation steps and operators needed by more than 50%, as well as WIP and floorspace requirement. With web-fed platen die cutting, you can save by buying reels not sheets and eliminate sheeting or pile turning.

SheetWizard 1650 (65 in) / 1850 (73 in) Dual Rotary Sheeter

The SheetWizard Dual Rotary Sheeter offers flexible and cost-effective configurations to suit many converters, folding carton plants, and mills. It runs both paper and board, providing superior cut quality and accuracy, featuring a unique dual-rotary knife.

SheetRunner 1850 (73 in) Dual Rotary Sheeter

The SheetRunner is a dual-rotary sheeting system for folding carton plants and commercial printers. Optimized for high-volume board production, this machine features brushless, liquid-cooled, high-torque knife cylinder motors to reduce maintenance and lower power consumption.

Falcon 2000 / 2500 Synchro Sheeter

Folding Carton

Talk to a BW Papersystems' Folding Carton expert to find our about what machine is the best solution for you and your folding carton production process. We can even conduct trials or provide output calculation to see potential improvement opportunities.

Contact us to learn more about how we can support your Folding Carton business

Folio Sheeters Designed to Handle Variable Sheet Sizes

Our folio-size sheeters are designed to handle a variety of large-size sheets at high-speeds to meet your production goals. BW Papersystems folio-size sheeters operate at variable size ranges from 400mm to 1650mm. To discover whether our machines can handle your sheet size, contact us today. Our knowledgeable team can help customize a machine for you.

Equipment Fully Customized to Your Specifications

Folio-size sheeters from BW Papersystems can be configured for a wide range of materials depending on the needs of your production. Customization options include reject gates, automatic positioning slitters, two or four position edge guiding system, tab inserters, inline embossing, programmable decurling, and more.

Web-Fed Platen Die-Cutting for Highest Productivity

Our web-fed platen die cutting lines operate at up to 1000 ft/min. (305 m/min.) with 425 ipm, performing with unyielding precision. Web-fed operation means substantially less waste because with web-fed there is no need for a 6-10 mm gripper margin on every sheet. In addition, the flexibility for nested layouts is far greater with web-fed, greatly reducing stripping waste.

No matter if from sheet or roll - we have the right solution for your folding carton production. Have a look at our solutions and contact us to learn more.

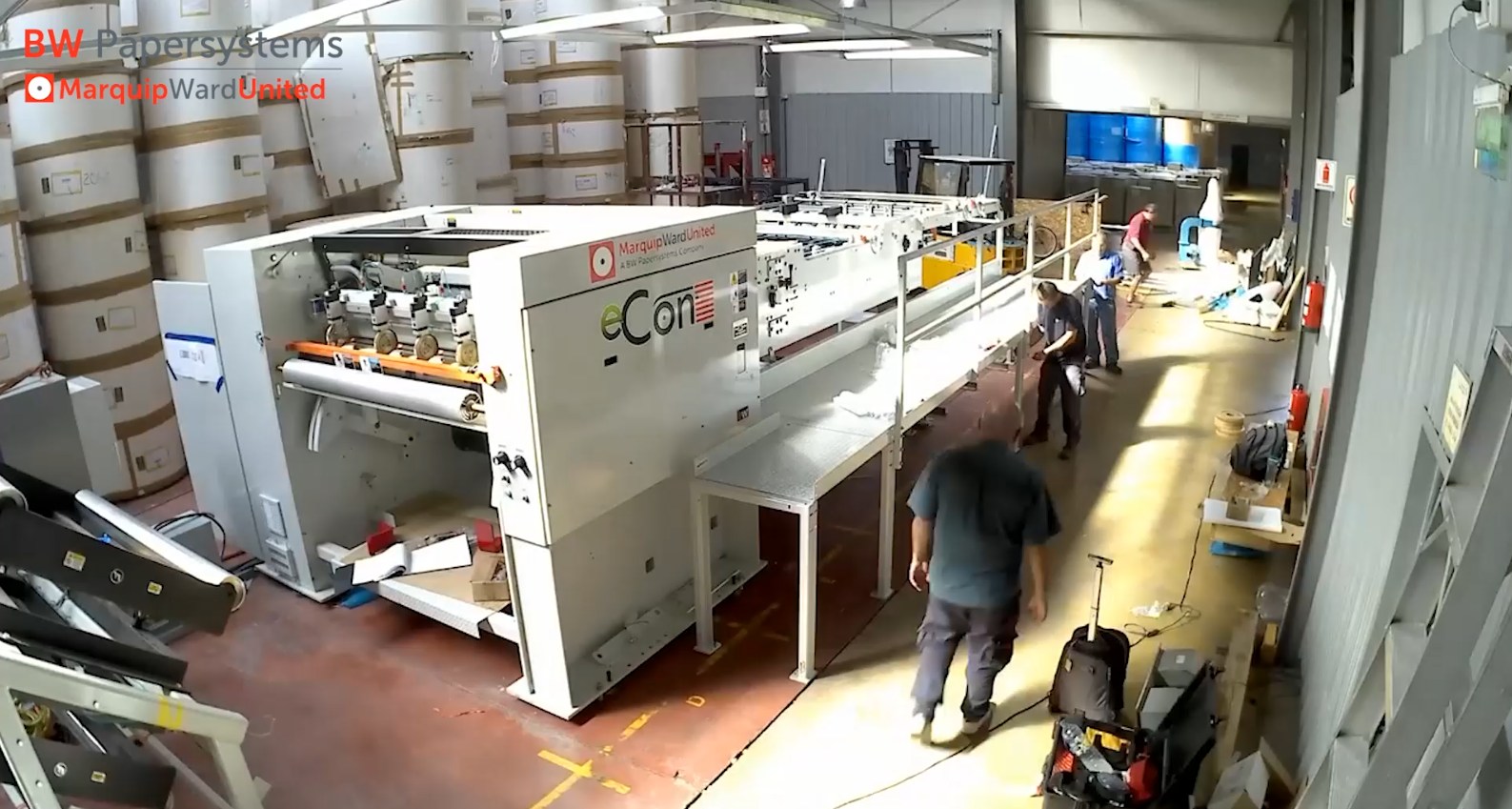

eCon Sheeter - Installation timelapse at customer Corti, Argentina

The MarquipWardUnited eCon Sheeter is a world-class machine. It’s not only easy to operate and maintain but it's also easy and quick to install. It takes a little bit longer than in this timelapse though... Enjoy and watch the eCon sheeter being installed at our customer Corti in Argentina.

Watch VideoTechnical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry.

Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

Since we added the new sheeter to our plant last year, we have seen an increase in productivity of at least 50% compared to our older folio sheeter.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)