Zerand

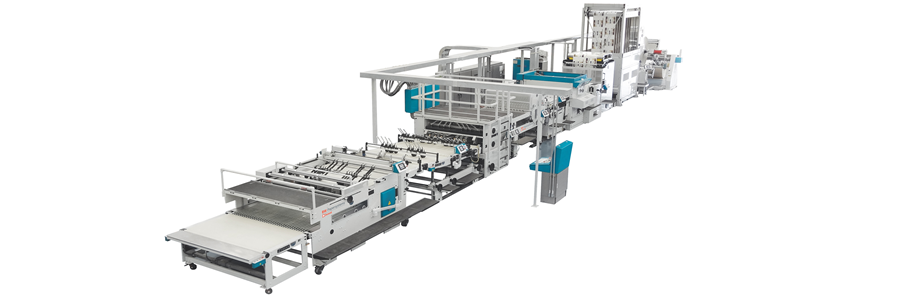

Web-Fed Platen Die Cutter

Web-fed Platen Die Cutters - 1400 (55 in)

Zerand web-fed platen die cutter lines are the most efficient way to to produce a folding carton. The platen die cutters offers highest productivity and a reduced board usage with nesting layouts and no gripper margins. They also reduce operation steps and operators needed by more than 50%, as well as WIP and floorspace requirement. With web-fed platen die cutting, you can save by buying reels not sheets and eliminate sheeting or pile turning.

Upgrades

With our extensive experience, we have developed a wide variety of upgrades and Technical Improvement Programs to keep your BW Papersystems equipment prepared for future production demands.

The Technichal Improvement Program offers a catalogue of standard upgrades for attractive conditions.

We wanted our next 55” Zerand die-cutter from BW Papersystems to be the first machine installed in the new building.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)