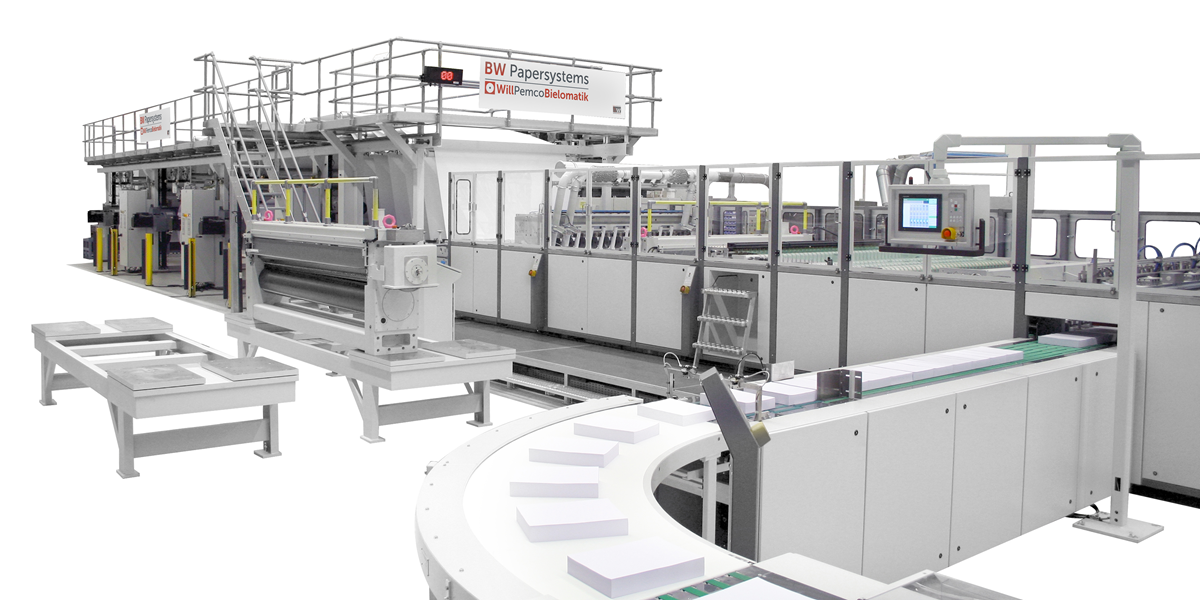

SLK 470 High-Performance Cut-Size Sheeter

Product Description

Highly automated, high-performance cut-size paper production

Available with 11 up to 16 pockets, the SLK 470 series offers intelligent processes and sophisticated technologies to provide trouble-free, non-stop and efficient production. A highly automated sheeter for a production of up to 800 tonnes per day – at minimum order sizes of only 1 pallet. No matter what volume: perfect ream quality is guaranteed.

- High speed production of up to 256 reams per minute

- Fewer operators required due to high automation level

- Non-stop reel change, special unwind design for efficiency

- Variation in number of reams directed to left or right discharge during production

- Movable operation terminal with touch screen

- Easily exchangeable slitter bottom knife shaft

- Sliding acoustic guards

- Efficient order handling through Manufacturing Execution System (MES)

- Large paper mills

Product Features

The SLK 470 is a highly automated, high-performance cut-size paper sheeter. It provides trouble-free, non-stop and efficient production of up to 800 tonnes per day – at minimum order sizes of only 1 pallet. The machine is available with 11 up to 16 pockets.

High Speed Production

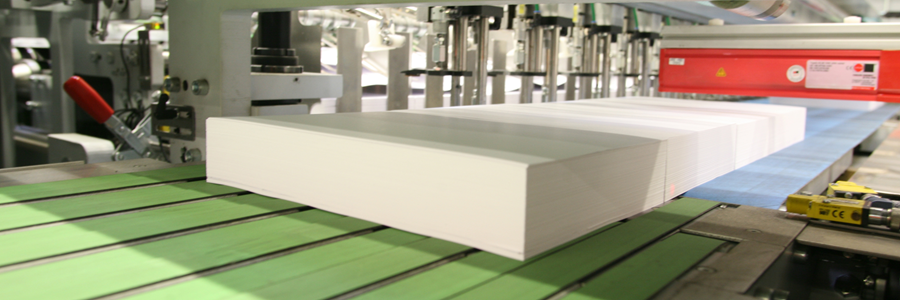

Excellent Cut Quality & Precision

Automation & Manufacturing Execution System (MES)

Trouble-free Production

| Working Width (max.) | 2400 mm / 2600 mm / 2820 mm / 3050 mm / 3250 mm / 3480 mm |

| Pockets | 11 / 12 / 13 / 14 / 15 / 16 |

| Reel width (min.) | 930 - 2010 mm |

| Reel width (max.) | 2475 - 3535 mm |

| Reel diameter (mm) | 1600 mm |

| Ream height (max.) | 130 mm |

| Output (reams per min.) -Single discharge- | 150 reams |

| Output (reams per min.) -Dual discharge- | 198 - 256 reams |

| Speed (max.) | 370 - 420 m/min. |

| Working strokes | 16 - 18 |

| Size width | 180 mm (min.) |

| Size length | 257 mm (min.) 432 mm (max.) |

| Cutting tolerance | +/- 0,2 mm |

| Cross cutter knife load (max.) | 600 gsm |

SLK 470 High-Performance Cut-Size Sheeter

Compare With

High-performance cut-size sheeting

Flexible, cost efficient production

The paper converting sector is highly competitive. Hence, flexible but efficient production, fast delivery times and quality are key. Play the game and always stay one step ahead of your competitor: the high level of automation combined with consistent product quality of the SLK 470 series from WillPemcoBielomatik enable you to attain your desired growth in the most cost-effective way.

Automation & Manufacturing Execution System (MES)

Cut quality and precision at its best

Like all cut-size sheeters from WillPemcoBielomatik, also the SLK 470 sets benchmarks in terms of cut and ream quality. A precision cross cutter with advanced knife technology and a dual slitter ensure that all quality standards (angle accuracy, cutting tolerance and cut quality) are fulfilled.

Optimal configuration for increased productivity

The SLK 470 models are available with 11 up to 16 pockets, allowing for an impressive output of up to 256 reams per minute. The number of reams directed left and right at the discharge can be varied even during production. Compatible, fully automated WillPemcoBielomatik packaging systems complement the high productivity of your line.

Simple operation

System solutions for cut-size sheeter SLK 470

- WillPemcoBielomatik inline packaging systems

- Ream wrapper

- Ream labeler

- Ream inspection / rejection

- Ream stacker / accumulator

- Case packer

- Case labeler

- Case inspection / rejection

- Interfaces for integrating palletizers & pallet packaging

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)