Model 32 Intermediate Ream Wrapper

Product Description

- Wraps all metric & standard U.S. ream sizes, including half-ream packages

- Simple machine operation with touch screen, including display of guiding instructions (e.g. for registered wrap, glue, adjustments)

- Servo driven machine for reliable performance

- Perfect ream control, glue application and wrap quality

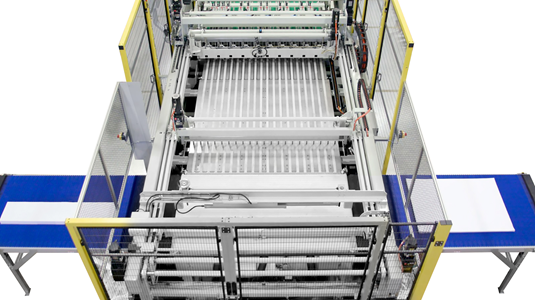

- Small, compact footprint with electrical enclosure mounted in machine

- Centralized hot melt glue system

Easy synchronization with sheeter

Ideal for...

- Smaller converters of standard paper reams

Product Features

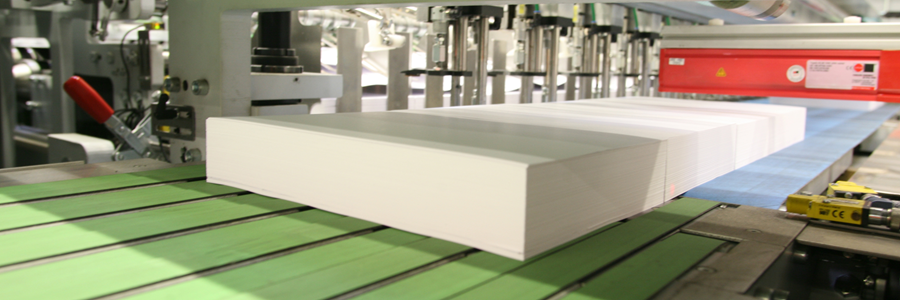

The fully automatic Model 32 ream wrapper is designed for mid-speed wrapping of all metric and standard U.S. ream sizes including half-ream packages. It allows for automated operation and precise registration of pre-printed wrap and can run standard Kraft as well as polypropylene ream wrap. It offers versatile wrap feeding: both roll and sheet feeding of ream wrap are possible.

Precise Ream Handling

Product Quality

Compact Machine

Simple Operation

| Metric | Imperial | |

|---|---|---|

| Package size range | 255 - 520 mm (length) 175 - 360 mm (width) 20 - 125 mm (height) | 10 in - 20.5 in (length) 7 in - 14 in (width) 0.8 in - 5 in (height) |

| Roll stand | up to 1270 mm diameter roll | up to 50 in diameter roll |

| Production speed | up to 80 reams per minute | |

Model 32 Intermediate Ream Wrapper

Compare With

- Wrapper print registration

- “Low-wrapper” roll warning

- Lincoln automatic lubrication

- Air conditioned electrical cabinet

- Roll stand to accommodate a 30 in / 762 mm roll

- Siemens PLC

- Vacuum choke bars

Ideal wrapper for intermediate speed wrapping

For wrapping of all metric and standard U.S. ream sizes including half-ream packages at up to 80 reams per minute, the Model 32 from WillPemcoBielomatik is your best choice. Advanced engineering features include roll feeding and sheet feeding of wrap, with the option for a wider roll.

Precise and smart ream handling

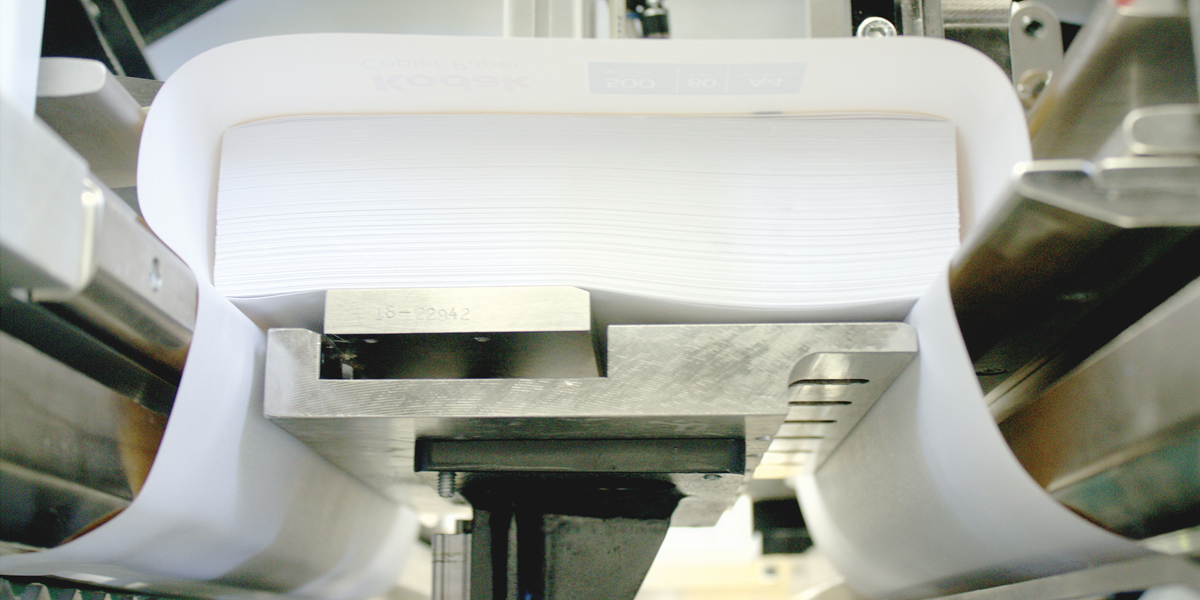

Reams are fed into the wrapper via a servo-driven, smart and flightless conveyor that also accepts and corrects for variance in ream spacing. The reams are guided gently from behind by emerging loading fingers. Prior to wrapping, these fingers and a ream squaring assembly position the reams precisely and, during the wrapping, a fixed ream stop maintains the consistent paper position prior to every wrap to ensure accurate and reliable wrapping quality for each ream.

Operator interface with touch screen

A touch screen simplifies machine operation, it also allows to perform machine diagnostics. Its display screen diagrams the machine layout to aid operator control and guides the operators with a registration instruction sequence when running registered wrap. Glue setup instructions and adjustments further facilitate operation.

Compact, servo driven machine for reliable performance

Centralized Nordson hot melt glue system

System solutions for cut-size ream wrapper Model 32

- Various WillPemcoBielomatik cut-size (e.g. SLK Procut) or digital-size (e.g. SHM Digicut) sheeter models

- Further WillPemcoBielomatik packaging machines

- Ream inspector

- Ream stacker/accumulator

- Case packer/lidder

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)