Mondi Syktyvkar, Russia, sets high targets for their cut-size machines and wants to exceed them in 2016 – with one of the top 10 pocket machines in the market

Mondi Syktyvkar is one of the leaders in the pulp and paper industry and the biggest paper producer in Russia. The company produces office and offset paper as well as newsprint, containerboard, liquid packaging containerboard grades and market pulp.

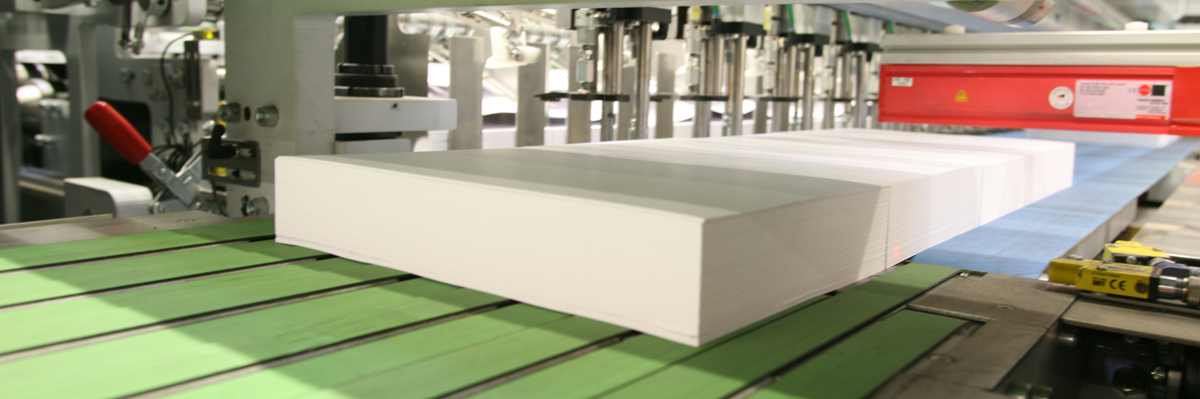

The Syktyvkar mill covers its office paper production with their three cut-size lines – a 6 pockets sheeter built in 1997 with 5 single backstands, a 10 pockets sheeter built in 2002 with 6 double backstands and a 12 pockets sheeter built in 2002 with 5 single backstands with adjacent packaging lines, all originally supplied by E.C.H. Will and Pemco (now WillPemcoBielomatik, BW Papersystems).

In 2015, Mondi Syktyvkar set itself some ambitious targets for its cut-size production.

The goal for 2016: a constant increased production with their existing production lines, without any investment into new faster and more efficient equipment.

At the end of 2015, the early results already exceeded all expectations almost reaching the 2016 target.

How did they achieve this?

With a perfectly balanced package of upgrades, spare parts and continuous support from the customer service team of BW Papersystems Hamburg. Based on audits of the three lines by service engineers from BW Papersystems Hamburg, the condition of the machines and needed improvements were determined and spare part packages for each section of the machines were defined. An upgrade from WillPemcoBielomatik’s Technical Improvement Program, the TIP module “New wider brake rollers” was installed in order to reduce a potential source of marking and to allow for higher production speeds.

During three service interventions in 2015, the parts and the TIP upgrade were installed. The BW Papersystems Hamburg service engineers also worked on optimizing the machine set-up which helped to stabilize and improve the performance of the cut-size and packaging lines. The result: an increased production volume, improved ream quality and maximum machine uptime.

What is the outcome?

All three cut-size lines at Mondi Syktyvkar are performing extremely well, meeting or exceeding their targets. The highly efficient 10 pocket cut-size line of 2002 with its six double unwind stands now is one of the top 10 pocket machines in the market. After the service interventions, the production increased by 6-10 % and the number of shutdowns related to market requirements (e.g. cut quality related) decreased to a fascinating zero. These figures greatly show the improved quality, the constant production – and there are further possibilities to grow. With this increase in production, the investment for upgrades, spare parts and service already paid for itself within a very short time.

What is Mondi’s plan for 2016?

In 2016, Mondi aims to permanently reach a higher daily production level. In order to achieve this target, they will work closely together with the complete customer service team of BW Papersystems. For sure, there will be another success story to share soon.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)