Model 124 Paper Ream Inspection System

Product Description

- Precise inspection of all reams with electric eye technology

- Up to 150 reams per minute can be scanned

- Defective reams are automatically rejected in-line and diverted to a storage conveyor

- Simple machine operation including handwheel adjustment for ream length

- Touch screen interface

- Single speed drive motor and programmable logic controller

- Options include vision system, missed label detection & laser end fold system

- All converters of standard paper ream sizes

Product Features

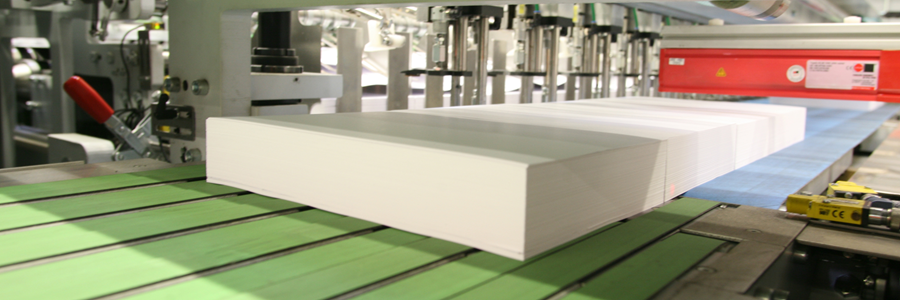

The Model 124 protects your product quality with precise, accurate inspection of wrapped reams: eight pairs of fiber optic eyes scan every ream edge-to-edge for loose or trailing labels, loose or improper wrap, or out-of-package sheets. Defective reams are automatically rejected inline and diverted to a storage conveyor before they get into the case.

Ream Quality

Performance & Flexibility

Various Options

Simple Operation

| Metric | Imperial | |

|---|---|---|

| Package size range | 254 - 520 mm (length) 178 - 360 mm (width) 19 - 127 mm (height) | 10 in - 20.5 in (length) 7 in - 14 in (width) 0.75 in - 5 in (height) |

| Production Speed | up to 150 reams/minute | |

Model 124 Paper Ream Inspection System

Compare With

Precise inspection of up to 150 reams per minute

Simple operation with touch screen interface

Option: Missed label detection system

Option: Label vision system

Option: Laser end fold system

System solutions for ream inspection/rejection Model 124

- Various WillPemcoBielomatik cut-size (e.g. SLK Procut) or digital-size (e.g. SHM Digicut) sheeter models

- Further WillPemcoBielomatik packaging machines

- Ream wrapper

- Ream stacker / accumulator

- Case packer/lidder

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)