Model 33 Flexible Ream Wrapper

Product Description

- Wraps all metric ream sizes from Japanese B5 to GTO (364 mm x 520 mm)

- 30 minutes or less manual ream size changeovers

- Option: Semi-automatic size change with programmable recipes for size changes in 10 min. or less

- Precise wrap placement & glue application

- Simple machine operation with touch screen

- Automatic lubrication

- Servo driven machine for reliable performance & reduced maintenance

- Compact footprint (electrical enclosure mounted in machine) & easy accessible design

- Easy synchronization with sheeter

- Integrated paper mills & converters of metric paper sizes

Product Features

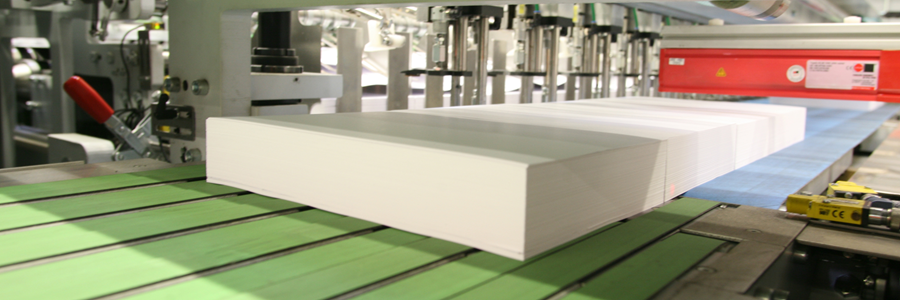

The Model 33 ream wrapper combines speed (up to 120 reams/min., A4), servo drive technology, and ream size flexibility. It is designed for worldwide metric standards and precise ream packaging in kraft, laminate & polypropylene wrapping materials.

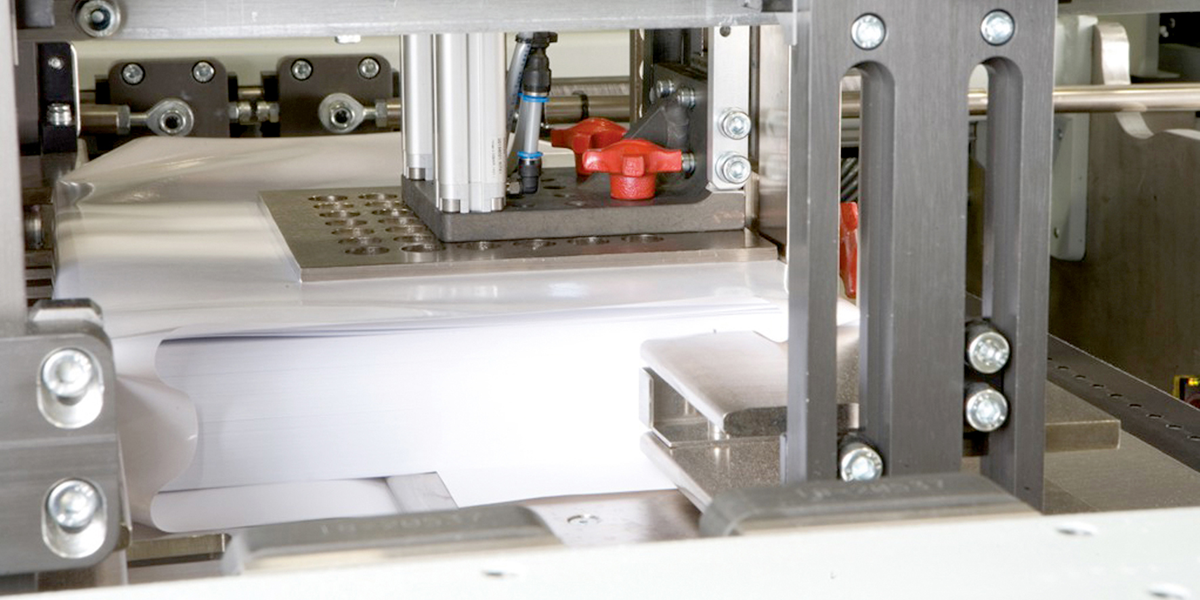

Precise Ream Handling

Product Quality

Compact Machine

Simple Operation

| Metric | Imperial | |

|---|---|---|

| Package size range | 250 - 460 mm (length) optional length: up to 525 mm 175 - 305 mm (width) optional width: up to 365 mm 20 - 125 mm (height) | 9.8 in - 18 in (length) optional length: up to 525 mm 7 in - 12 in (width) optional width: up to 365 mm 0.8 in - 5 in (height) |

| Roll stand | up to 1270 mm diameter roll | up to 50 in diameter roll |

| Production speed | up to 120 reams per minute (A4) up to 75 reams per minute (A3) | |

Model 33 Flexible Ream Wrapper

Compare With

Ideal wrapper for high-speed wrapping of metric sizes

Precise and efficient ream wrapping

Optional semi-automatic size change

Operator interface with touch screen

Servo driven machine for reliable performance

Accessible machine with a compact footprint

System solutions for cut-size ream wrapper Model 33

- WillPemcoBielomatik cut-size sheeters (e.g. SLK 490 (7-10 pockets) and SLK 470 (11-16 pockets)

- Further WillPemcoBielomatik packaging machines

- Ream labeler

- Ream inspection/rejection

- Ream stacker / accumulator

- Case packer/lidder

- Case labeler

- Case inspection/rejection

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)