Corrugated Finishing Machines

World leader in corrugated finishing equipment

Need to get the job done faster, more efficiently and with fewer wasted resources? BW Papersystems is a global provider of top-tier corrugated finishing equipment. We provide the world’s leading corrugated finishing equipment, including flexo folder gluers, rotary die cutters, and ancillary equipment such as the Twin Box Slitter and Vacuum Overhead Stacker. Save time and increase your production output with BW Papersystems. Contact us to learn more about how our corrugated finishers are perfect for your line.

BW Papersystems World-Class Corrugated Finishing Machines

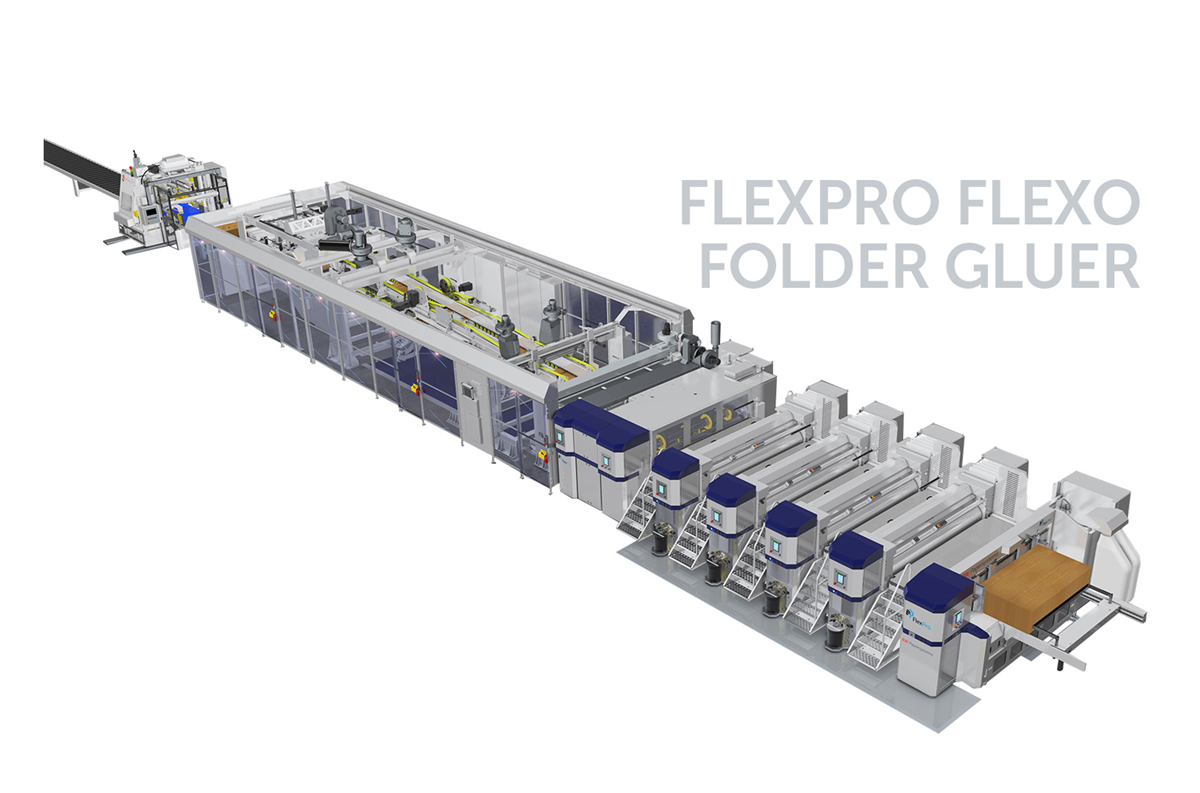

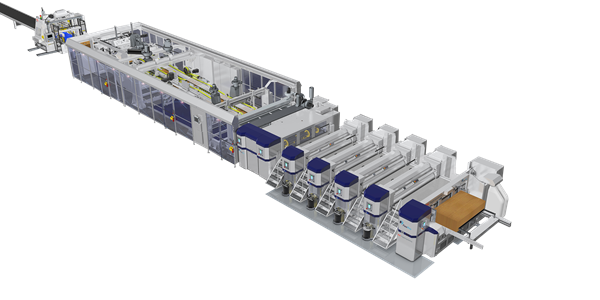

FlexPro Flexo Folder Gluer

The FlexPro is the latest finishing innovation from the BW Papersystems team—a rugged, set-while-run Flexo Folder Gluer engineered for long-term performance and versatility. Designed with a fully integrated die-cutter, the FlexPro delivers exceptional folding accuracy and high-quality print results across a broad range of applications.

Technical Service

Contact our Technical Service for Installation, Rebuilds, Relocation, Training, and much more.

Why Partner with BW Papersystems?

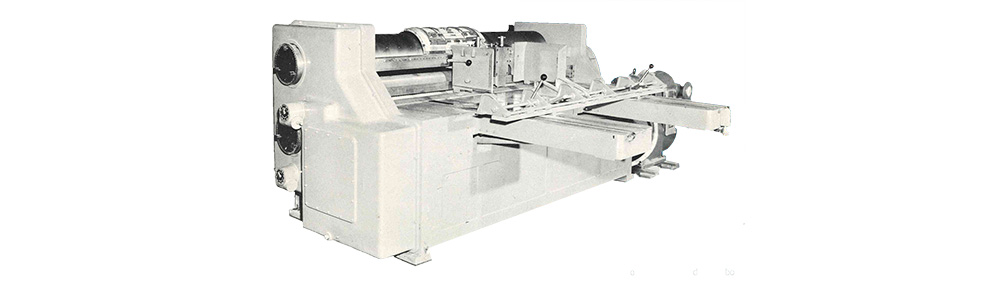

We offer control integration and customization on machines built to last. Our rotary die cutters and flexo folder gluers have a legacy of durability and we offer constant support to companies that partner with us. Learn more about our corrugated finishing equipment below.

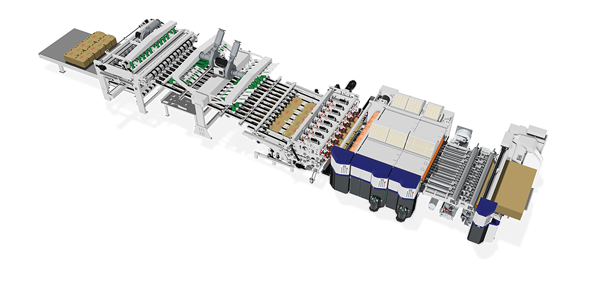

Innovative Control Integrations

We offer advanced control integration. Our rotary die cutters and flexo folder gluers offer streamlined controls and integrate with our stacker and Twin Box Slitter. We will also work with other OEM suppliers to provide end-to-end integration solutions from pre-feeders through palletizers. . Together, we can make your production line, faster, more efficient, and easier to use and maintain.

The BW Legacy of Durability

Corrugated Finishing Customization Options

Why Choose BW Papersystems for Your Twin Box Slitter?

BW Papersystems makes it easy to get more boxes out of the line you already have. The Twin Box Slitter® adds capacity without adding a second Flexo Folder Gluer, helps keep changeovers down, and delivers clean, consistent cuts. All of our machines are backed by OEM parts and a team that knows these machines inside and out. We can assist with installation, operational training, and even remote troubleshooting.

Upgrades

With our extensive experience, we have developed a wide variety of upgrades and Technical Improvement Programs to keep your BW Papersystems equipment prepared for future production demands.

The Technical Improvement Program offers a catalog of standard upgrades.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)