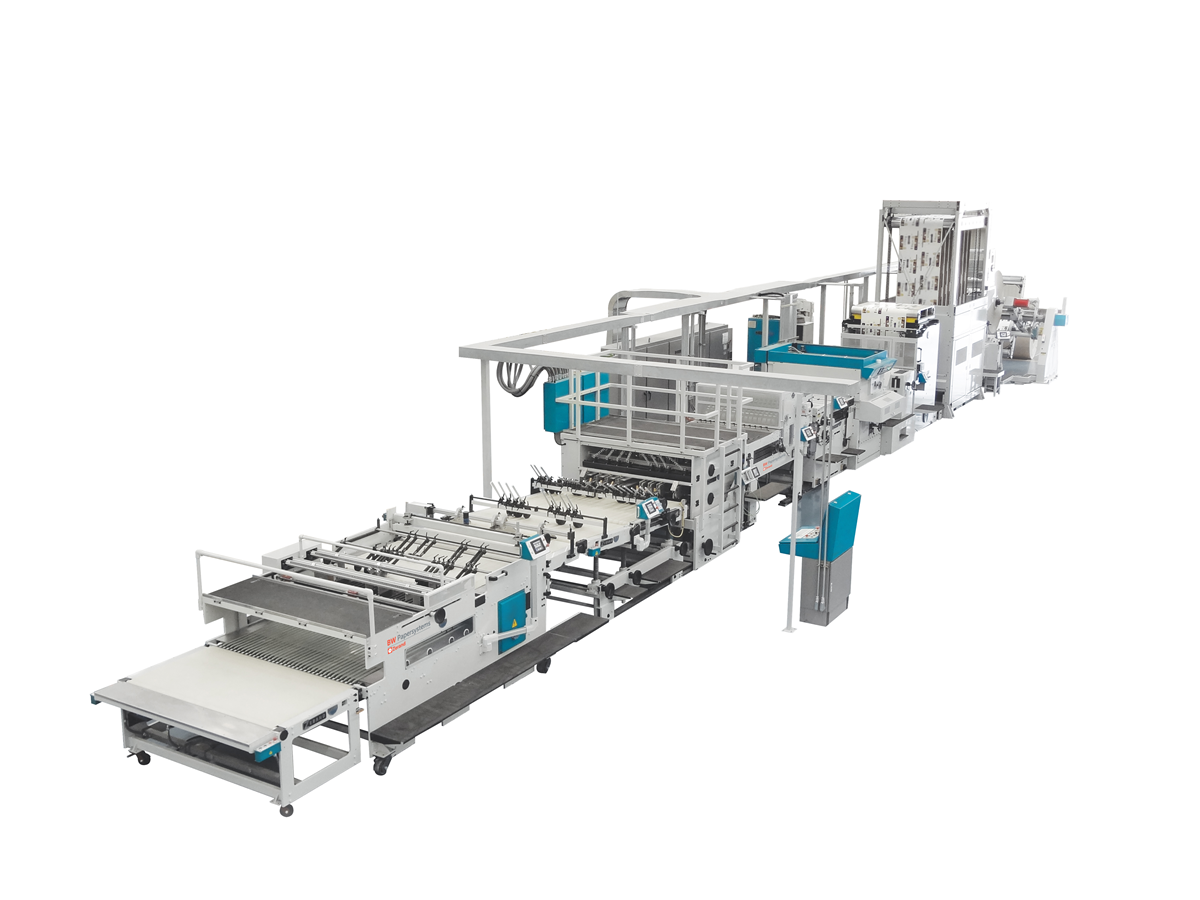

Web-fed Platen Die Cutters - 1400 (55 in)

Product Description

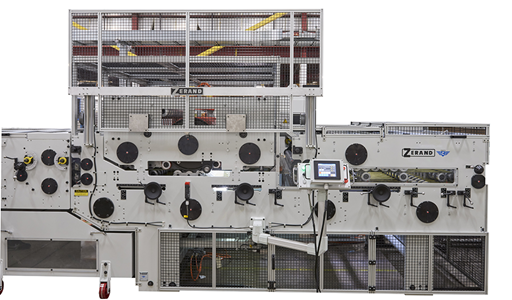

Zerand Web-Fed Platen Die Cutter Line – 1400 (55 in)

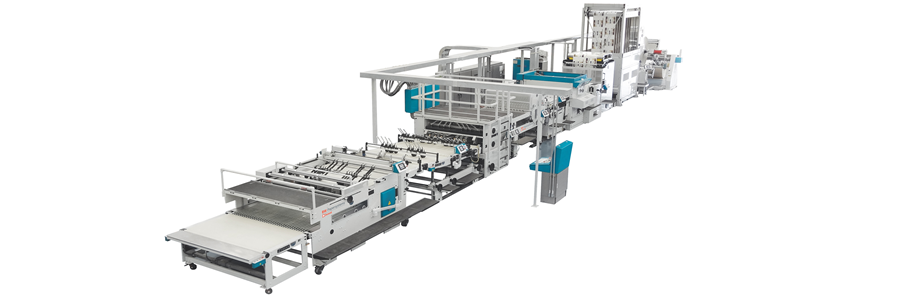

The Zerand web-fed platen die cutter line is the most efficient way to produce a folding carton. Our flatbed die cutters offer the highest productivity and reduced board usage with nesting layouts and no gripper margins. They also minimize operation steps and operators needed by more than 50%. This equipment also minimizes WIP and floor space requirements.

With web-fed platen die cutting, you can save by buying reels instead of sheets and eliminate sheeting or pile turning. With Zerand web-fed flatbed die cutters, quick and quality go hand-in-hand.

Web-Fed

Platen Die Cutter Benefits

- Highest productivity (equal to the output of 2.5 sheet-fed platen cutters)

- Significant reduction of board usage (eliminated gripper margin, using nesting layouts)

- Reduced operations and number of operators by more than 50%

- Reduced WIP and floorspace requirement

- Cost savings by buying reels not sheets and eliminating sheeting

Efficient and User-Friendly

These systems perform with unyielding precision. Motorized adjustments make them operator-friendly for an efficient, easy-to-use experience.

Reduced Operation Requirements

Web-fed operation means substantially less waste compared to sheet fed because with web-fed die cutting, it’s a Roll to Blank to Stack process. This process reduces plant storage and logistics, as there are fewer independent operations and movement of full pallets around the plant. Operations time and operators needed are cut in half while reducing WIP and floorspace requirements thanks to the end-to-end process.

Reduced Operation Costs

Web-fed operation means substantially less waste than sheet-fed because with web-fed, there is no need for a 6-10 mm gripper margin on every sheet. In addition, the flexibility for nested layouts is far greater with web-fed over sheet-fed, significantly reducing stripping waste. Less waste means a much lower operating cost for you.

Our web-fed platen die cutters also offer reduced costs by buying reels instead of sheets, hence eliminating sheeting and piling.

Product Features

Zerand web-fed platen die cutter lines are the most efficient and cost-effective way to produce a folding carton.

Increased Productivity

Highest productivity (equal to 2.5 sheet-fed platen cutters) with max. speed 300 m/min - 25,500 strokes per hour (wide web)

Reduced board usage

Reduced board usage by 18% by nesting blanks and by eliminating gripper margins and scrap between cut sheets (single knife cutting)

Reduced Changeover Times

Makeready made easy - the complete line is auto setup with recalling stored job parameters from job memory and offers quick tool change (for Cutter, Stripper & Stacker)

Low Tooling Cost

Low tooling cost for platen cutter dies, a stripper pin cylinder, and anvil roller that do not require additional cassettes and adjustable or custom-made stacker tools

| Specifications | Wide Web Cutter – 1000 ft/min. |

|---|---|

| Maximum Web Width: | 55 in (1400 mm) |

| Minimum Web Width: | 27 in (686 mm) |

| Maximum Cutoff: | 40 in (1016 mm) |

| Minimum Cutoff: | 18 in (457 mm) |

| Maximum Cutting Load: | 1,500,000 lbs. |

| Maximum Cut/Crease Rule: | 2700 in (65580 mm) |

| Substrate Thickness: | 0.010 in – 0.040 in (0,25 -1 mm) |

| Print To Cut Registration: | +/-0.010 in (+/- 0,25 mm), accuracy to key colour, under stable operating conditions |

| Register Control System: | Zerand or other suitable commercial registration system |

| Maximum Speed | 1000 ft/min. (305 m/min.) |

| Maximum Impressions | 425 ipm |

Web-fed Platen Die Cutters - 1400 (55 in)

Compare With

- Productivity:

- Max. speed 300 m/min - 25,500 strokes per hour (wide web)

- Fast makeready & Changeover:

- Auto Setup of the complete line, as all important locations and variables are stored by job and recalled when a job is repeated

- Motorized movement of all units

- Quick Tool Change (for Cutter, Stripper and Stacker)

- Low Tooling Cost

- Platen cutter dies

- Stripper pin cylinder and anvil roller without the need of additional cassettes

- Adjustable or custom-made stacker tools

- Low Scrap Rate:

- “Single Knife Cutting” without scrap between cut sheets

- “Nested Blanks”

- Easy to Use: with simple operator interface and full diagnostic system

- Easy to Interface: works well with other OEM’s

- ELS technology: Latest Bosch Rexroth Indramat technology for variable speed feed eliminates scuffing on poly coated board and other delicate materials

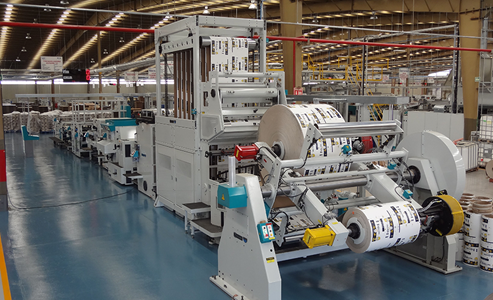

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)