Model 162 High-Speed Case Packer & Lidder

Product Description

- Precise casing of single or double stacked reams

- Up to 30 (singles) or 15 (doubles) cases per minute

- Smooth production with only limited operator interface

- Designed for use with flat, scored and slotted/die cut blanks

- Nordson ProBlue hot melt glue system assures perfect adhesion

Touch screen interface and programmable logic controller (PLC)

Ideal for...

- Integrated paper mills & converters of standard paper ream sizes

Product Features

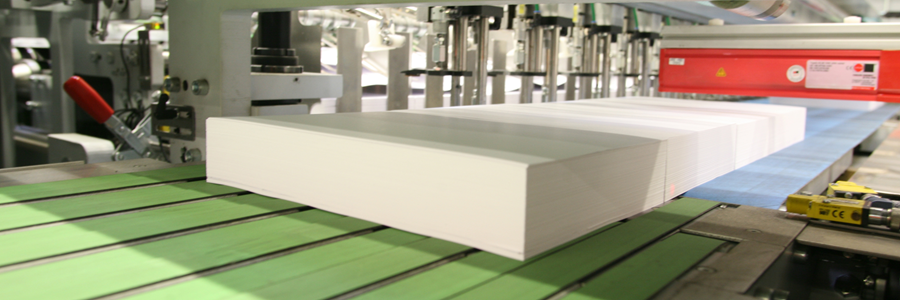

The precise, high-speed case packer / lidder Model 162 is a key component in a fully automated ream production line and only requires limited operator interface. It cases single or double stacked reams with precision fit every time, using the stack as a forming mandrel as case and lid blanks are formed around the stack and glued.

Precise Casing

Automation

Reliable Gluing

Simple Operation

| Metric | Imperial | |

|---|---|---|

| Case size range | 267 - 470 mm (length) 210 - 362 mm (width) 152 - 445 mm (height) | 10.5 in - 18.5 in (length) 8.25 in - 14.25 in (width) 6 in - 17.5 in (height) |

| Production Speed | single stack - up to 30 cases/minute double stack - up to 15 cases/minute | |

| Lid flap range | 70 - 102 mm (minimum to maximum) | 2.75 in to 4 in (minimum to maximum) |

Model 162 High-Speed Case Packer & Lidder

Compare With

High-speed, precise casing of up to 30 cases (singles stacks) per minute

Fully-automated with only limited operator interface

Precise casing and lidding process

Enhanced lid feed fault recovery

Touchscreen and PLC simplify machine operation

Nordson ProBlue hot melt system for reliable gluing

System solutions for case packer/lidder Model 162

- WillPemcoBielomatik cut-size sheeters (e.g. SLK 490 (7-10 pockets) or SLK 470 (11-16 pockets))

- Further WillPemcoBielomatik packaging machines

- Ream wrapper

- Ream labeler

- Ream inspection/rejection

- Ream stacker/accumulator

- Case labeler

- Case inspection/rejection

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)