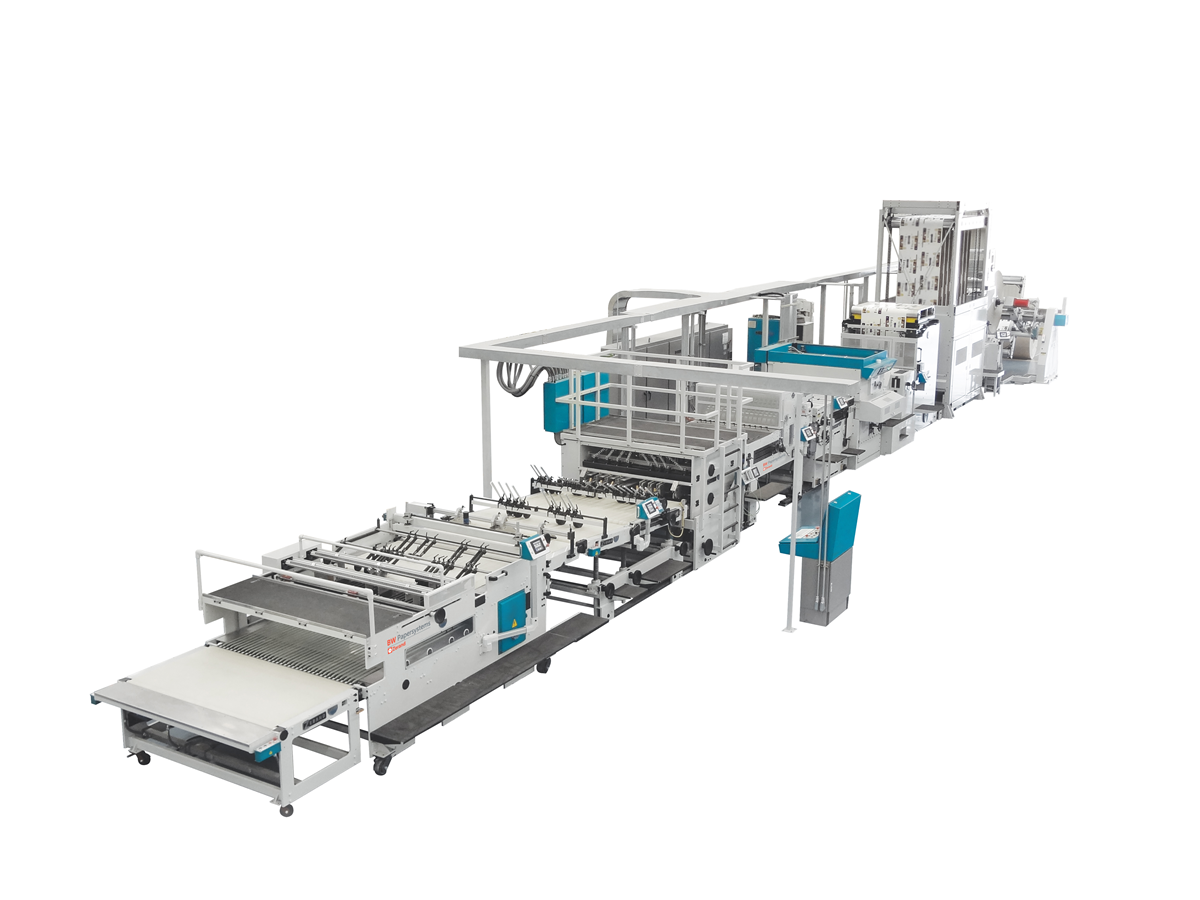

Carton Stacker

Product Description

The Stacker unit, receives carton streams from the Gap Generator, parallel streams of shingled cartons are conveyed to the Carton Stacker. The Interface Conveyor, an integral part of the Stacker, couples the Stacker and Gap Generator together. The Interface Conveyor it is equipped with vibrating “plows” to align and guide the cartons into the stacker and delivers the streams of carton blanks to the magazine at a rate equal to the speed of the Gap Generator conveyor. This provides a continuous flow of cartons to the stacker magazine. Wheels on the slow-belt conveyor stabilize and Jogger plates control the streams of carton blanks as they travel to the magazine.

When the stacks reach a predetermined height, the discharge cycle initiates automatically, then are deposited onto the Discharge Conveyor for transport downstream for disposition. (normally a Receiving Table)

Product Features

Quick Change

Auto Setup

Auto setup of the complete stacker cycle when job is repeated

Blank removal

Profile Stacking Tool

Main Stacker Characteristics (based on stacker models)

- Carton Length 3.0 in. to 40 in. (actual range limits vary by model)

- Maximum Stack Height

- 6 in. to 16 in. (actual height varies by model)

Carton Stacker

Compare With

- Ejection Cycle Controls

- Stack Height

- Stack Count (Number of Blanks)

- Quick Changeover Tools

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)