High-Speed Millennium Singlefacer

Product Description

- High speed operation 450mpm/1500fpm

- Pressure belt design with extended 100° wrap (most contact distance in the industry)

- Positive pressure for optimal shape retention

- Fast flute cassette change, made from either side of machine.

- Infusion preconditioning

- Rugged, reliable, resonance free construction

Product Features

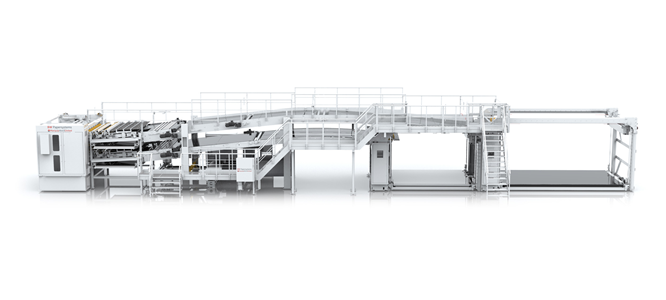

High speed

450mpm/1500fpm. The Millennium singlefacer is designed to optimize the two fundamental processes affecting board speed – bonding and flute formation. Periperal heated corrugating rolls, infusion preconditioning, web tension control and precise accurate glue application all contribute to high-speed reliable running.

Pressure belt design

Endless, breathable, pressure belt with a 100 degree wrap angle over the upper corrugating roll. More time for the bond to form and strengthen. Pressure belts help prevent damage to lighter weight papers and avoid pressure lines often seen on pressure roll singlefacers.

Positive Pressure chamber

United Container, one of the BW Papersystems legendary brands, pioneered the positive pressure fingerless technology. Positive Pressure is a self-purging system naturally expelling debris and dried starch. Maintenance and downtime issues associated with negative/vacuum systems that are sensitive to dirt and debris are eliminated. Does away with unplanned stops and delamination caused by negative vacuum pressure systems.

Infusion preconditioning

Millenium Singlefacer | |||

|---|---|---|---|

| Speed | 1500 fpm | 460 mpm | |

| Minimum Width | 98 in. | 2500 mm | |

| Maximum Width | 112 in. | 2850 mm | |

- Maximum board caliper

- Elimination of flute lines

- Ability to run all paper grades

- Ability to run printed liners at the single facer

- Superior Flute Formation

- Effective for all flute profiles & paper grades

- Maximum strength with minimal fiber

- Optimal liner conditioning

- Maximum bonding with optimal glue application

- Flatter board

User Friendly Flute Change

- 5 minute no-tool flute change

- Side loading modules for maximum flexibility

- Pre-heated modules for immediate production

- Designed for years of low cost reliable operation

- Provides maximum uptime and minimal downtime

- Low cost of ownership with maximum return

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

a2a25e0f-43cd-43f0-9c3f-a5cc11fbcc29.jpg?sfvrsn=4dd9e7f_1)

359d5a13-484b-4d53-ac6f-d25f42158726.jpg?sfvrsn=c8dd9e7f_1)

.jpg?sfvrsn=a0dd9e7f_1)