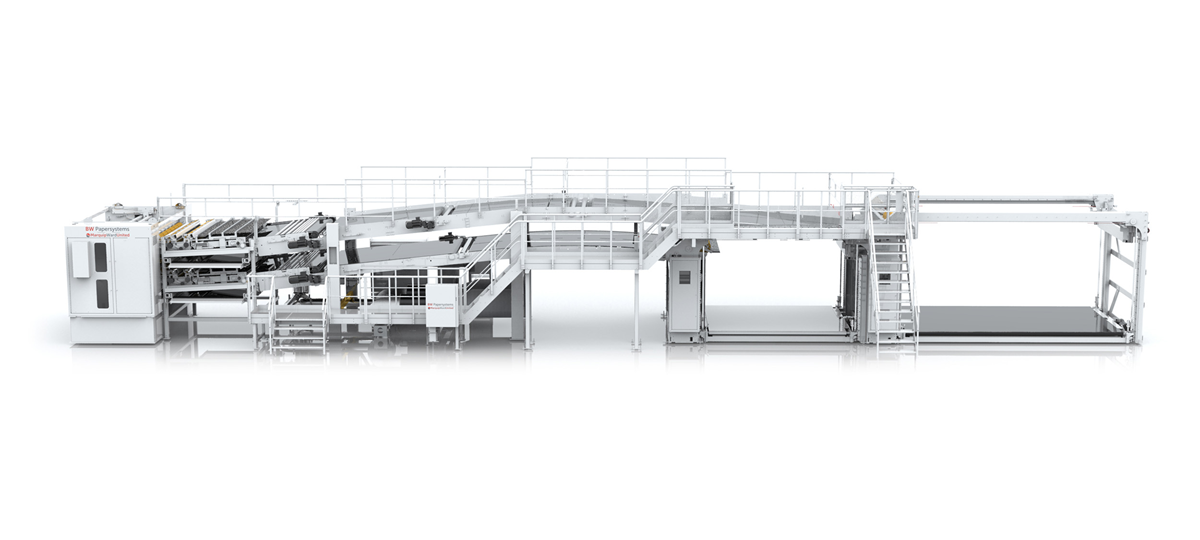

Performance Corrugator Series

Product Description

- Reliability and Board Quality are the pillars on which our corrugator designs are based.

- Fiber Reduction is an important issue for corrugated plants, and our corrugators were designed to also handle lighter basis weight papers.

- Post Sale Support is essential to work as a partner to your corrugated operation. Our highly experienced customer service representatives will provide a lasting commitment for the life of our corrugator.

- We will support you with onsite and remote service, detailed diagnostics and training.

We are your supplier for a proven solution. The modular design of our machines and the high performance levels are exactly tailored to your needs. Our years of experience and our modifiable corrugator lines, allow us to meet small capacity requirements and also high capacity requirements with speeds up to 460mpm (1500fpm).

Product Features

Fast-loading rollstands, high-speed splicers, dependable singlefacers, a doublefacer with crushless technology, razor slit cutting, oilless knife cutting, and excellent stack

Top Quality

Control System

Versatility

| Production Speed | 300 mpm - 350 mpm - 400 mpm - 460 mpm | 1000 fpm - 1150 fpm - 1300 fpm - 1500 fpm |

| Width | 2500 mm - 2850 mm | 98 in. - 112 in. |

| Average Capacity | +14 - 18 million m2 / month | 150 - 190 million sq ft / month |

Performance Corrugator Series

Compare With

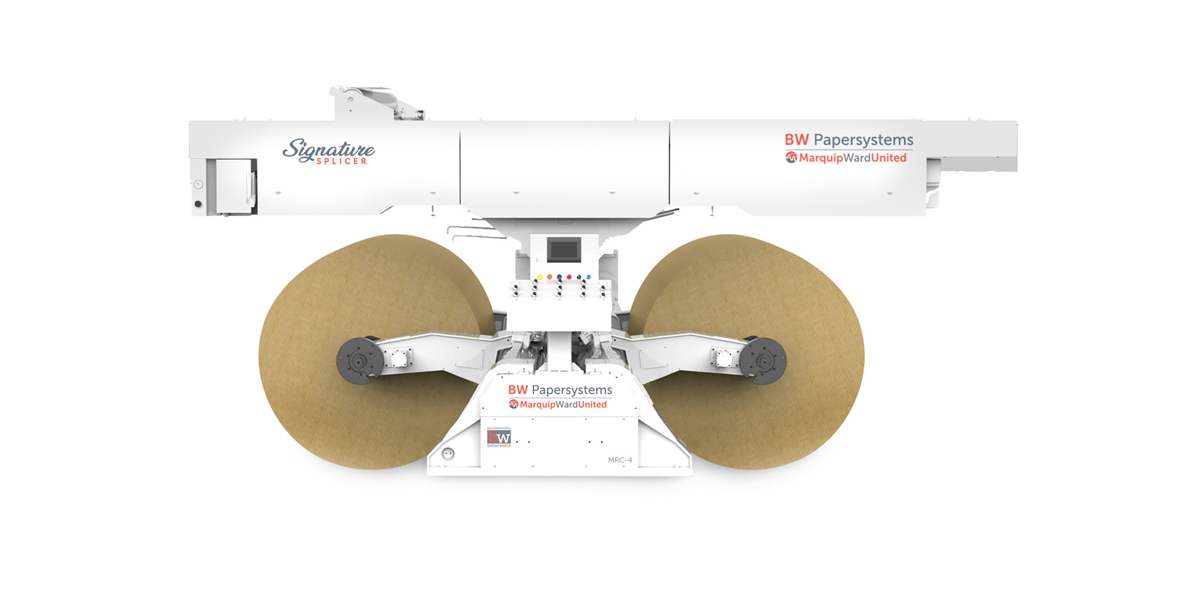

- High Speed Performance

- Featuring the Signature Splicer for superior splicing reliability

- Vacuum Traction Section eliminates the possibility of board crush in the traction section

- Superior traction is provided without the use of a nip to pull the board

- Board caliper and stiffness are increased

- Improved board quality with no curing time means an immediate conversion

- The industry's narrowest trim specification on the Slitter Scorer that allows significant payback in trim waste reduction

- The Fusion Knife / Stacker delivers superior web and sheet control

- Ease of maintenance

Performance Corrugator

BW Papersystems designs all of its machines to produce high-quality results every time. As a leading corrugator machine manufacturer, we offer efficient and effective solutions to support corrugating businesses. This commitment allows us to continue providing customers with the highest quality products.

Watch VideoFind Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)