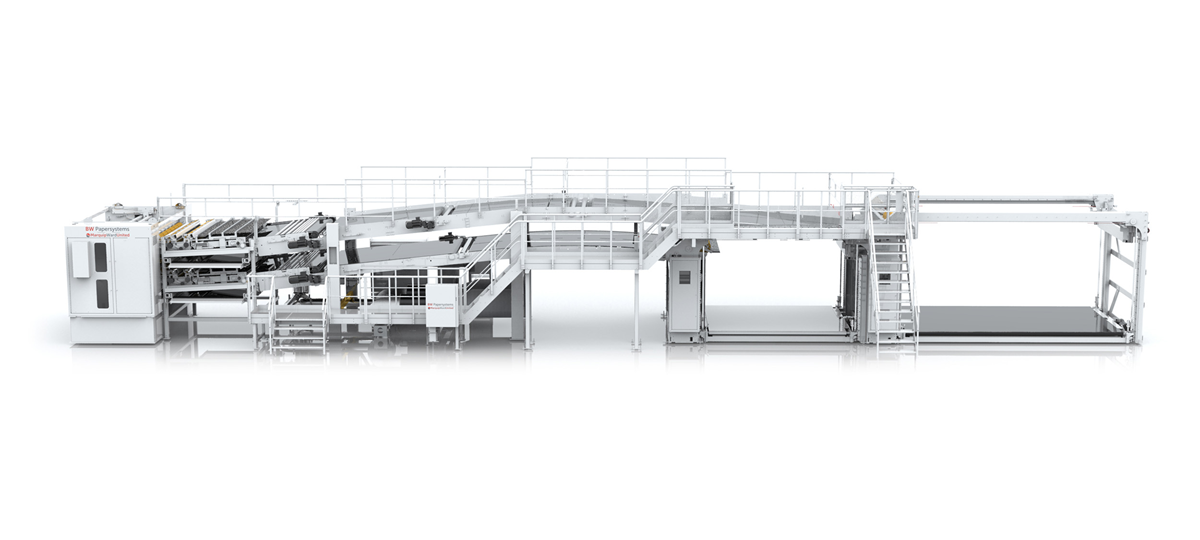

BW Papersystems is a premier corrugator manufacturer with a wide range of complete corrugators and corrugator components to match your specific production needs. Every plant has different requirements with respect to performance and quality within

the context of paper types, paper grades, web width, overall production capacity and speed. BW Papersystems corrugators are customized to meet those specific requirements.

These solutions are categorized as Performance, Harmony, and Value Corrugators. Each corrugator line features a customizable dry end to meet your plant’s productions goals.

The Performance Corrugator offers maximum production and board quality. This line features the Sentinel, a complete corrugator control system, which automatically optimizes all process variables, monitors board quality, and facilitates information

to be communicated throughout the corrugator.

The BW Papersystems Performance Corrugator features the RPS Express Slitter Scorer. The RPS Express features robotic setup for precise accuracy with plunge activation for line speed order changes. Dry end order changes are easily performed

at speeds of 300 mpm (1000 fpm). The Trim Switch™ feature ensures the downstream slitting section (adjacent to the trim chutes) always starts the new order trim. Tool setup accuracy of +/- 0.4 mm (0.015”) allows you to consistently

meet critical box specifications.

The Saber Knife from BW Papersystems incorporates legendary Marquip knife quality with industry leading cut length vs speed curve. The Saber Knife features cut capability up to 460 mpm (1500 fpm). Additional benefits of the Saber Knife include

industry-leading cut accuracy and zero board crush.

The Saber Knife features walk-in access for quicker maintenance for blade tuning and clearing jams. BW Papersystems’ High-Speed Cylinders provide the industry’s best blade tuning interval cycle, which also decreases knife maintenance.

The Saber Knife provides high performance with low energy consumption for increased efficiency.

One of the most recent developments for the Performance Corrugator Dry End is the Fusion Knife and Stacker. Designed to work as one unit, the Fusion offers a lower total cost of ownership as the design features a 40% reduction in parts. Shared

motion controls platform allows seamless interface and immediate connectivity of signals and conditions.

Additional benefits of the Fusion include line speed waste ejection and with the Eagle Eye, the first cut can be sellable product. The Fusion offers high speed performance and superior web control and stack quality in a variety of different

configurations in 2500 mm (98 inch) and 2850 mm (112 inch) widths. The Fusion is offered in 300 mpm (1000 fpm), 350 mpm (1150 fpm), 400 mpm (1300 fpm) and 460 mpm (1500 fpm).

By combining the RPS Express Slitter Scorer and Fusion Knife Stacker or Saber Knife, the Performance Dry End delivers superior board and stack quality at speeds up to 460 mpm (1500 fpm). The Performance Corrugator Dry End also features operator

friendly controls for the changing workforce.

If your production goals are more moderate to meet market demand, BW Papersystems’ Harmony Corrugator may be the perfect match. The Harmony Corrugator is designed for customers looking for a value on cost-to-performance, and a “crushless”

corrugator that offers quality board to satisfy your market requests.

The Harmony Corrugator is a customized solution with a modular design to meet your market needs. The Harmony Corrugator is available in 2500 mm (98 inch) and 2800 mm (110 inch) widths at speeds from 300 mpm (1,000 fpm) to 350 mpm (1,150 fpm).

BW Papersystems recently developed a slitter scorer and knife specifically for the Harmony Corrugator. Based on reliable and quality-driven corrugator components, these are the RSS Excel Slitter Scorer and the Saber Excel Knife.

The RSS Excel Slitter Scorer has multiple slit and score sections to set up tools on one section while tools on another section are operating. At order change, the tools will quickly lift out of the board line, while the new order tools plunge

in. Dry end order changes are easily performed at speeds of 300 mpm (1000 fpm).

MarquipWardUnited brand slitters are corrugated industry’s standard for slitting excellence with features such as individual on-head sharpening systems, rotating lower anvil supports, and use of a very thin blade. Clean slitting minimizes

dust, increases flexo productivity, improves printing quality, reduces edge trim, eliminates slit edge delamination, reduces feed table jams, and improves box squareness and curing.

The Saber Excel Knife is based on the Saber Knife, but with features and options that specifically designed and priced to meet moderate production goals. Like the Saber Knife, the Saber Excel Knife features legendary Marquip knife quality for

excellent cut accuracy.

The Harmony Dry End is a great option for plants looking to produce quality board at speeds up to 350 mpm (1150 fpm). This corrugator can be further customized to meet your needs.

The Value Corrugator is reliable and cost effective, with an emphasis on cost-to-performance ratio. The Value Corrugator, and its comprehensive management system, fits well in markets that require a high volume of order changes, with moderate demand for product output for narrow to wide widths. Value Corrugators can be configured in 1800 mm (70 inch), 2200 mm (87 inch), 2500 mm (98 inch) and 2850 mm (110 inch) widths with speeds from 200 mpm (650 fpm) to 350 mpm (1150 fpm).

The Value Dry End features a shear with Two cylinders for reliable cutting and scrap removal and trim cutter used for gapless order changes. The heads of the slitter scorer are positioned with individual servo motors for accuracy and fast order changes. The knife features helical wound blades with servo motor control provides cutting accuracy of +/-1mm. A DownStacker is standard, but an UpStacker is an option.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)