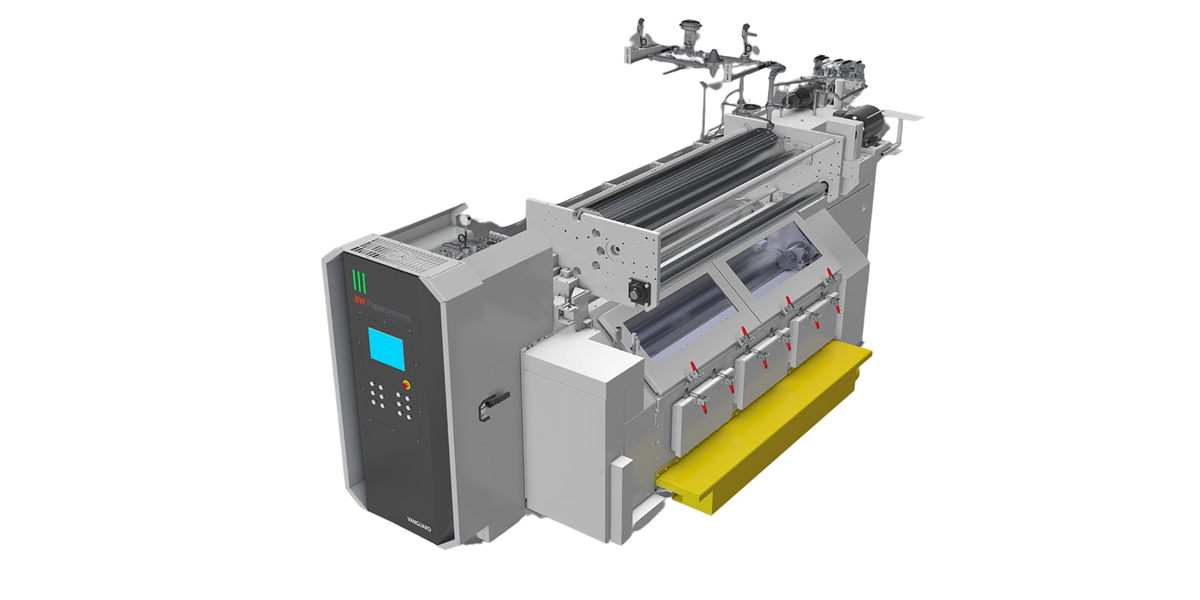

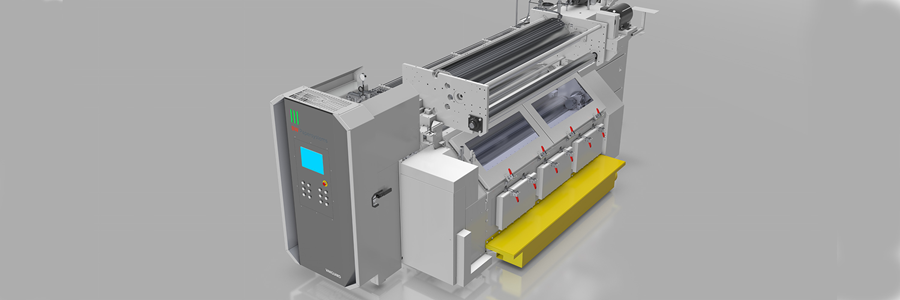

Vanguard SFG Singlefacer

Product Description

Pressure Roll Singlefacers from BW Papersystems

BW Papersystems offers the Vanguard SFG Singlefacer, engineered for continuous high-speed operation, and maximum uptime due to a unique medium preconditioning system, precise starch application and quality flute formation. With the Vanguard SFG Singlefacer, users can expect maximum productivity, superior board strength, and unsurpassed board quality.

When you add the Vanguard SGF Singlefacer to your corrugator, you can expect efficient and effective production to meet or exceed your requirements.

Learn more about the Vanguard SFG Singlefacer by contacting the BW Papersystems’ team today!

Features of the Vanguard Singlefacer from BW Papersystems

The Vanguard pressure roll singlefacer is designed with your production line in mind. It has features that set it apart from the others. The Vanguard accepts the widest variety of liners and medium to produce superior board quality. The large-diameter pressure roll provides maximum heat transfer and stability for excellent green bond strength and consistent flute quality. Learn more about the features of the Vanguard SFG Singlefacer below.

Proven & Reliable Technology

BW Papersystems has built and installed the Vanguard Singlefacer over 350 times, satisfying all market demands. This pressure roll Singlefacer is a proven high-speed runner used in the most productive plants in many integrated companies. It includes a pressure chamber blower system, and large accessible windows and doors for optimal performance and easy maintenance. Automation improvements have elevated the reliability, performance and capabilities of this industry standard Singlefacer, known by a new name – Vanguard SFG.

Maximum Productivity & Durability

BW Papersystems’ Vanguard SFG Singlefacer has hydraulically-loaded corrugating rolls and pressure roll to maintain high-speed stability with minimal operator adjustment. The driven pressure roll eliminates shear stress during the green bond formation for maximum board strength. United Container, one of the BW Papersystems legendary brands, pioneered the positive pressure fingerless technology to eliminate vacuum systems that are sensitive to debris.

Infusion Medium Pre-Conditioning

The BW Papersystems’ Vanguard SFG Singlefacer uses our patented Infusion technology that conditions the medium by penetrating the medium’s fibers with moisture and heat like no other system. This allows higher run speeds and improves board quality. In addition, it is effective for all flute profiles and paper grades. Additional preconditioning and water mixing systems are included in the Vanguard SFG model.

Unique Split Frame Design

BW Papersystems’ Vanguard SFG Singlefacer has a unique split frame design that includes a roll-out glue section for more efficient maintenance. The design also allows unrestricted access to the machine’s interior and incorporates a corrugated roll cart and module for more effective flute changes.

The Vanguard pressure roll singlefacer is designed with your production line in mind. It has features that set it apart from the others. The Vanguard accepts the widest variety of liners and medium to produce superior board quality. The large-diameter auto line pressure roll provides maximum heat transfer and stability for excellent green bond strength and consistent flute quality.

Learn more about the features of the Vanguard SFG Singlefacer below.

Superior Starch Application

The Vanguard SFG Singlefacer has motorized glue pans with a patented incline pan design for minimal starch application and constant circulation. It can be easily removed for maintenance and cleaning. BW Papersystems offers optional pans for narrower widths as well. A two door access gives operators a spacious and safe access to the glue application area.

Partner with BW Papersystems for the Durable & Productive Vanguard Singlefacer

When you add the Vanguard SFG Singlefacer to your corrugator line, you can expect a durable and productive pressure roll singlefacer that has low maintenance requirements and high-performance capabilities that can transform your production. Contact the BW Papersystems’ experts to discuss your equipment applications and requirements in more detail.

Product Features

The Vanguard SFG pressure roll singlefacer is designed with your production line in mind. It has features that set it apart from the others. The Vanguard accepts the widest variety of liners and medium to produce superior board quality. The large-diameter pressure roll provides maximum heat transfer and stability for excellent green bond strength and consistent flute quality. Rated corrugator speed of 400mpm/1300fpm.

Vertical stack rolls

Positive Pressure chamber

Automatic or Quick roll change

The corrugating rolls are housed in a cassette that can be changed through two systems. The ARS (Automatic Roll Change System) provides a hands-off cassette change that is safe, easy and quick. The QRS (Quick Roll Change System) requires some operator involvement but no manual tools during the simple, efficient roll change procedure.

Medium pre-conditioning and glue application

The Vanguard SFG is unmatched in conditioning medium, thanks to its patented Infusion™ system that penetrates paper fibers with heat and moisture for better board quality and faster run speeds. A separate capstan roll ensures precise tension, while optional steam control handles tough mediums. Its advanced glue system adjusts levels automatically for cleaner, more reliable operation, and now includes improved glue pans, a pre-rinse package, and optional automatic glue dam tracking.

Vanguard Singlefacer | |||

|---|---|---|---|

| Speed | 1300 fpm | 400 mpm | |

| Maximum Width | 98 in. / 112 in. | 2500 mm / 2850 mm | |

Vanguard SFG Singlefacer

- Speed

- Minimum Width

- Maximum Width

- 400 mpm

- 2500 mm

- 2850 mm

- 1300 fpm

- 98 in.

- 112 in.

Compare With

Designed for Maximum Productivity

- Pressure roll design for running maximum paper grades at high speed

- Superior liner to medium bonding for maximum board strength

- Optimally design corrugated rolls

- Minimal crowns for superior cross machine formation of all flutes

- Optimal flute formation for maximum board strength

- Maximum stability for high speed throughput

Infusion Pre-Conditioning

- Infusion Pre-Conditioning standard feature.

- Additional Steam showers with water mixing system available.

- Superior flute formation

- Automatic, precision control of paper tension

- Effective for all flute profiles & paper grades

- Maximum strength with minimal fiber

Unique Split Frame Design

- Rollaway glue section for effective & efficient housekeeping

- Unrestricted access to machine’s interior for maintenance

- Automatic corrugated roll cassette ejection system for fast flute changes

Durable Design

- Modern design, focused on operator ergonomics and maintenance access.

- Designed for years of low-cost reliable operation

- Provides maximum uptime and minimal downtime

- Low cost of ownership with maximum return

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)