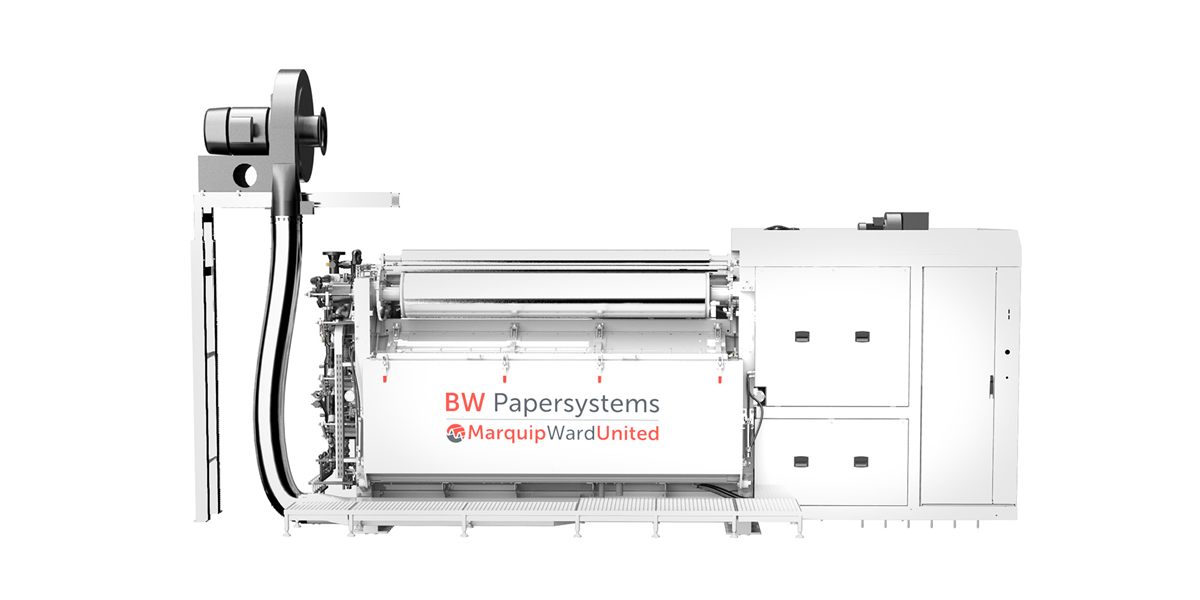

Advantage Singlefacer

Product Description

Designed to meet the needs of the global market

Highlights

- Compact footprint

- Metric sizes

- Enhanced automation

- Designed to run different kinds of paper

Product Features

Engineered to provide reliable operation and maximum uptime. The Advantage singlefacer accepts the widest variety of mediums and liners to produce superior board quality. Available in 2500mm/98” or 2850mm/112” widths and operational up to 400 mpm/1300fpm.

- Large corrugating, preheating and pressure rolls

- Fast flute change

- Positive pressure design

- Modern PC and Servo controls

- Modular design for easy machine access

Large corrugating, preheating and pressure rolls

Fast flute change

Positive pressure design

Modern PC and Servo controls

Advantage Singlefacer | |||

|---|---|---|---|

| Speed | 1310 fpm | 400 mpm | |

| Maximum Width | 98 in. / 112 in. | 2500 mm / 2850 mm | |

Advantage Singlefacer

- Speed

- Minimum Width

- Maximum Width

- 400 mpm

- 2500 mm

- 2850 mm

- 1310 fpm

- 98 in.

- 112 in.

Compare With

Superior Flute Formation

- Low crown corrugated rolls create excellent cross machine fluting

- Large diameter pressure roll for smooth stable operation at all speeds

Designed for all Paper Grades

- Servo driven gap controls for repeatable precision operation

- On-board liner & medium pre-heating with adjustable wrap arms

- Automatic starch metering control

- Automatic glue gap control

- Automatic corrugated roll module calibration at flute change

- Automatic temperature monitoring & control (optional)

- State of the Art PC control with user friendly icon driven HMI

- Optional external infusion style medium pre-conditioner for higher paper grades at maximum speed

Infusion (on-board) Pre-Conditioning

- Superior flute formation

- Precision control of paper tension

- Effective for all flute profiles & paper grades

- Maximum strength with minimal fiber

Flute Change Flexibility

- User friendly 8 minute roll module change

- Side loading modules for maximum flexibility

- Pre-heated modules for immediate production

Maximum Productivity

- Rollout glue system for total machine access to facilitate housekeeping & maintenance

- PC based diagnostics & VPN access to maintain maximum uptime

- Durable construction for long term production and reliability

- Built for low cost of ownership and maximum return on investment

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

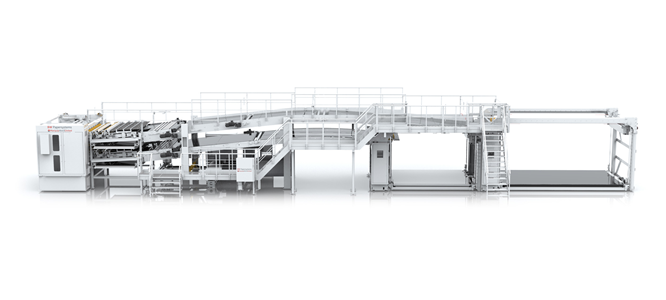

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)