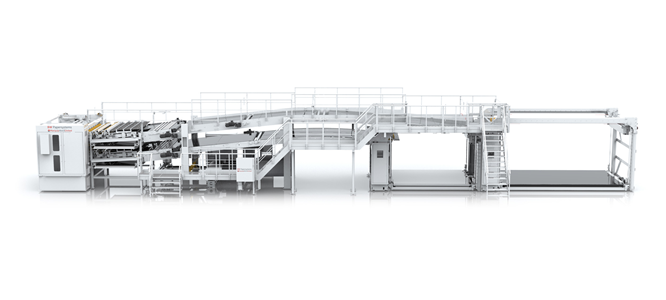

Eagle Glue Machine

Product Description

- Precision motorized glue gap control automatically adjusts the quantity and pattern of glue which is transferred to the flute tips

- Rider roll with automatic Soft Touch™ Gap control

- Precise rider roll gap adjustment ensures proper adhesive transfer even with micro-flute

- Glue transfer mechanism rolls out for easy clean-up, inspection and maintenance

- Automatic glue dams that can preset to the running web width

- Inclined, low-volume glue pan design eliminates starch gelling. Facilitates wash up, and automatically controls starch level

- Regenerative drive modules reduce energy consumption

Product Features

The Eagle Glue Machine motor/encoder assembly drives a zero backlash jack screw arrangement to provide excellent accuracy on both the metering roll to glue roll and rider roll to glue roll adjustments

Automatic Glue Gap Control

Energy Efficient

Easy Clean up and Maintenance

Automatic Glue Dams

| Imperial | Metric | |

|---|---|---|

| Width | 98 in. - 112 in. | 2.5 m - 2.85 m |

| Maximum Speed | 1500 fpm | 460 mpm |

Eagle Glue Machine

- Width

- Maximum Speed

- 2,5 m | 2,85 m

- 460 mpm

- 98 in. - 112 in.

- 1500 fpm

Compare With

- Precision motorized glue gap control automatically adjusts the quantity and pattern of glue which is transferred to the flute tips

- Rider Roll with automatic Soft Touch™ Gap control

- Precise rider roll gap adjustment ensures proper adhesive transfer even with micro-flute

- Glue Transfer Mechanism rolls out for easy clean-up, inspection and maintenance

- Inclined, low-volume glue pan design eliminates starch gelling. Facilitates wash up, and automatically controls starch level

- Regenerative drive modules reduce energy consumption

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)