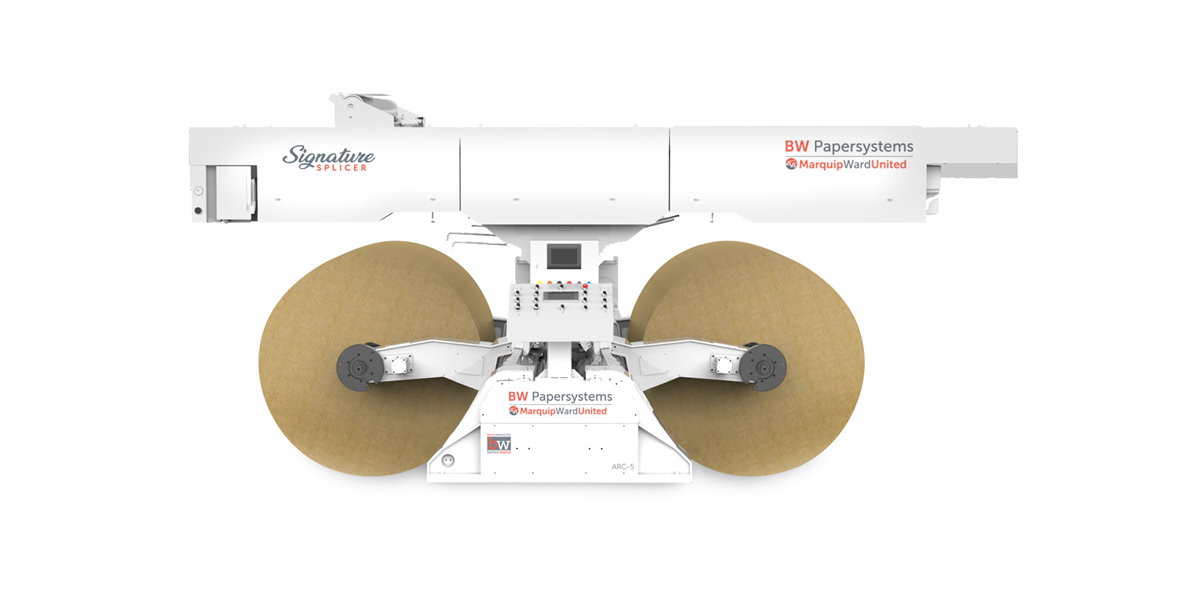

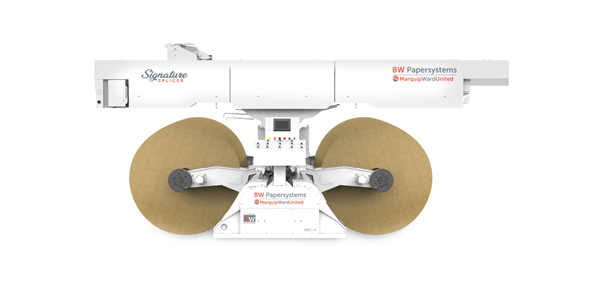

ARC-5 Corrugator Roll Stand

Product Description

The ARC-5 Roll Stand is a robust, high-value and low maintenance roll stand that is configured for efficient and economic manual or semi-automatic roll loading.

Other Highlights:

- Self-centering roll positioning

- Small Diameter roll pickup

- Heavy duty Brakes and chucks

- Core-Stripping capability

- Low Profile / Small footprint

- High Speed spindles

Product Features

Simple, durable, and robust design

High speed movement

Automatic roll loading, lifting and unloading

Butt roll loading and core stripping device

| Imperial | Metric | |

|---|---|---|

| Lifting Capacity | 1100 lb | 5000 kg |

| Minimum Roll Width - 98.4 in. | 2500 mm | 36 in. | 915 mm |

| Minimum Roll Width - 112 in. | 2800 mm | 46 in. | 1168 mm |

| Minimum Roll Pickup Diameter - Manual | 12 in. | 305 mm |

| Minimum Roll Pickup Diameter - Automatic | 16 in. | 405 mm |

| Arm Spacing in the Machine Direction | 100 in | 2540 mm |

ARC-5 Corrugator Roll Stand

- Lifting Capacity

- Minimum Roll Width - 98.4 in. | 2500 mm

- Minimum Roll Width - 112 in. | 2800 mm

- Minimum Roll Pickup Diameter - Manual

- Minimum Roll Pickup Diameter - Automatic

- Arm Spacing in the Machine Direction

- 5000 kg

- 915 mm

- 1168 mm

- 305 mm

- 405 mm

- 2540 mm

- 1100 lb

- 36 in.

- 46 in.

- 12 in.

- 16 in.

- 100 in.

Compare With

- Rigid 240mm (9.5”) diameter steel torque tubes

- Double hydraulic cylinder design to prevent deflection

- Quick roll loading and unloading allows short wet end orders to be run efficiently.

- Pneumatic disc brakes and high-speed spindles facilitate the efficient running of butt rolls.

- Low energy consumption with automatic shut off of the hydraulic pump motor.

- Heavy-duty torque tubes and dual side arm cylinders provide maximum durability for alignment of spindles.

- Includes track/trolley operator controls and interface to provide seamless operation with BW Papersystems and other common tracks.

- Vital for Efficient Wet End Operations

- Efficient running of Butt Rolls

- Rigid mechanical design with solid steel torque shafts provide superior torsional

characteristics - Oil-impregnated, low-fiction nylon bushings on pivot points and linear slides ensure smooth operation

- Arms that slide on precision ground keys offer excellent durability and corrosion resistance

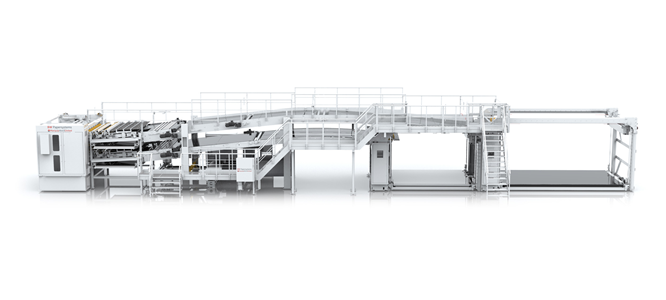

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)