Key Container adds Vanguard SFG Singlefacer

Original article reposted from the IPBI Magazine

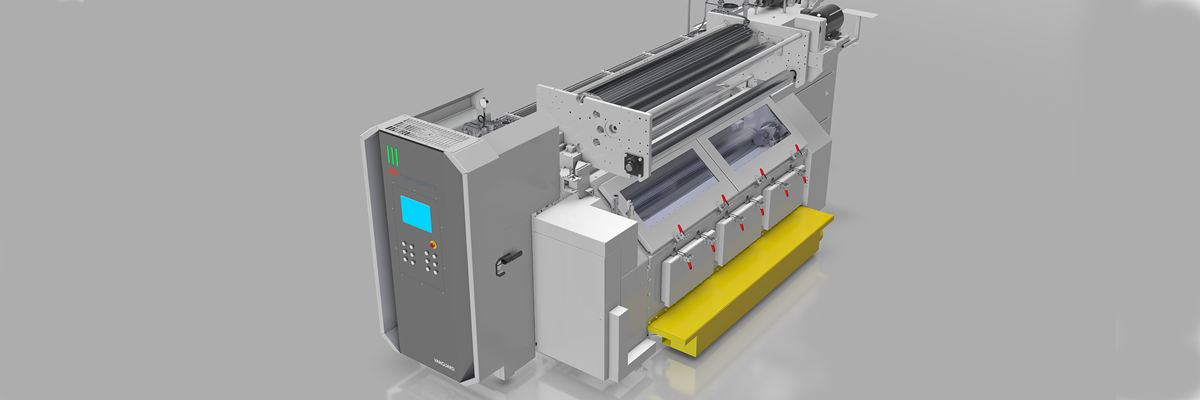

BW Papersystems is advancing one of its most trusted machines with the introduction of the Vanguard SFG Singlefacer. This next-generation singlefacer integrates the latest automation and process control technologies and is designed to improve board quality, productivity, and operational efficiency. Advanced moisture control systems condition both the liner and medium webs, ensuring optimal bonding across all paper weights and types. Operators can now produce high-quality singleface board at high speed with greater ease. Additionally, the machine’s automated diagnostics and monitoring capabilities provide real-time insights, allowing operators to identify and address potential issues before they impact production.

Key Container’s Experience with the Vanguard SFG

The intuitive user interface allows operators of varying experience levels to efficiently manage production, reducing training time and increasing overall operational effectiveness.

Advanced Automation for Safer, More Efficient Operations

The Vanguard SFG incorporates a suite of automation features designed to enhance productivity, consistency, and safety in corrugating operations. Key features include:

- Automation to simplify operation: the automated glue gap control, corrugating roll loading, pressure roll loading, and medium tension control allow operators to run high quality singleface board at maximum machine speeds with minimal manual intervention.

- Automation to drive consistent board quality: the moisture control system precisely manages liner and medium preconditioning, ensuring consistent bonding and reducing defects. The system adjusts automatically based on production variables, reducing inconsistencies.

- Automation to reduce downtime: advanced diagnostics and real-time monitoring provide alerts for potential issues, minimizing unscheduled downtime. Additional features such as glue level sensing and a glue roll pre-rinse cycle improve operational efficiency and machine cleanliness. The system also allows for predictive maintenance, helping to prevent unplanned outages.

Redefining Singlefacer Technology

As part of BW Papersystems’ ongoing innovation strategy, the Vanguard SFG integrates cutting-edge automation and process control to redefine industry standards. By utilizing intelligent sensors and automated adjustments, the singlefacer is designed to reduce waste, increase energy efficiency, and maintain consistent production quality. Jeff Gafner, P.E., Senior Vice President, highlights BW Papersystems’ commitment to industry innovation. He said, “Through a relentless commitment to innovation, we are reshaping the future for corrugating lines. We are not just meeting industry standards – we are defining them, creating solutions that drive the next generation of operational excellence for our customers and a vibrant future for our team members.”

A Future-ready Solution

The Vanguard SFG represents a step forward in corrugated manufacturing, offering a combination of automation, reliability, and efficiency. With its ability to streamline operations, improve board quality, and reduce downtime, it is designed to meet the evolving demands of the industry. Companies investing in the Vanguard SFG can expect greater consistency, reduced labor costs, and increased throughput, providing them with a competitive edge in the market.

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)