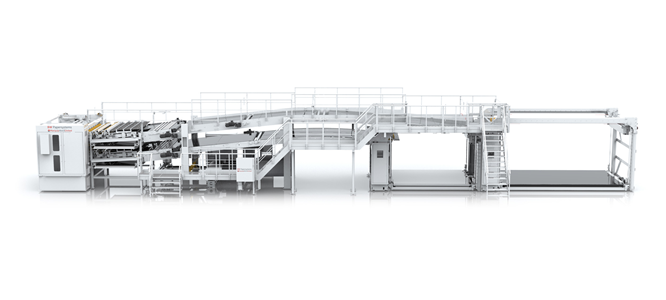

Saber Cutoff Knife

Product Description

- Cut capability up to 450 mpm (1500 fpm)

- Industry-leading cut accuracy

- High performance with low energy consumption

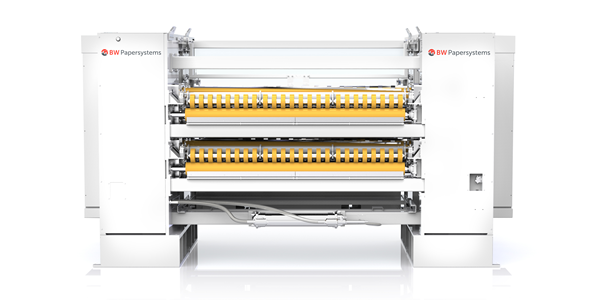

- No board crush design

- BWP High-Speed (HS) Cylinders provide the industry’s best blade tuning interval cycle, which decreases knife maintenance

- Walk in access allows for quicker maintenance for blade tuning and clearing jams

Product Features

Saber Knife offers the performance and reliability that will improve profitability for any corrugator plant. Short sheets can be cut at much higher speeds for a significant production increase.

- Cut capability up to 450 mpm (1500 fpm).

- Superior cylinder performance with excellent cut accuracy and extended intervals between blade tuning.

- High performance with low energy consumption.

- Closed-loop, liquid-cooling system keeps contaminants out for improved reliability.

- Walk-in access is convenient and safe.

- Simplified controls design reduces maintenance costs.

Industry leading speed curve up to 450 mpm

Superior Cylinder Performance

High Performance and low energy consumption

Closed-loop, liquid cooled system

- Minimum sheet length: 430 mm (17 inches)

- Industries leading cut length accuracy

| Knife Series | Typical Corrugator Speed |

|---|---|

| 50L | 260mpm (850fpm) |

| 100L | 365mpm (1200fpm) |

| 150L | 400mpm (1300fpm) |

| 200L | 450mpm (1500fpm) |

Saber Cutoff Knife

Compare With

- Superior Cut Length vs. Speed Performance

- Lowest Energy Consumption

- Designed for Greater Levels of Reliability

- Easy, Safe Operator and Maintenance Access

- Reduced Maintenance Increases Uptime

- The Crushless Corrugator Knife

- Cut-To-Leading Edge

- TailTracker

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)