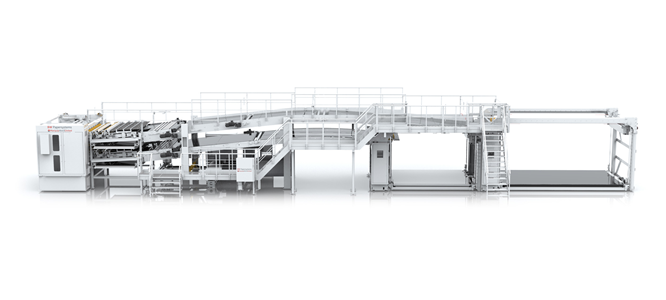

Excel Slitter-Scorer

Product Description

The Excel Slitter/Scorer has, as standard, one slit and two score sections with the option to add another score section (automatic or manual) if required. The score tools on one section preset while tools on the other section are operating. At order change, the score tools quickly lift out of the board line, while the new order tools plunge in. The individual servo motor positioning slit tools, with on-head sharpening and lubrication, rapidly reset to the next order positions for back-to-back order changes. Its compact footprint and modern controls allow integration into most corrugator lines.

Product Features

- Superior slit quality with the industry’s narrowest trim specification

- Industry-leading head setup accuracy

- Superior Score Flexibility

- Narrow score tool spacing to yield maximum scoring flexibility

- Efficient production of short orders

- Small footprint, single station machine

- Simple design for ease of access and low maintenance requirements

Superior Slit Quality

Industry Leading Accuracy

Superior Score Flexibility with narrow spacing

Short Order production

- Tool setup accuracy of +/- 0.4 mm (0.015”) results in consistent critical box specifications.

- Minimum trim width of 6mm (0.25”)

- Guards swing away to provide improved access to the tooling heads

- Touch-screen operator interface enhances control

Excel Slitter-Scorer

Compare With

- Industries narrowest trim specification allows significant payback in trim waste reduction.

- Industry-leading head setup accuracy.

- Precise score depth

- Excellent operator & maintenance access.

- Small footprint, single station machine.

- Simple design with low maintenance requirements.

- Narrow score tool spacing to yield maximum scoring flexibility.

- Excellent slit quality using a rotating anvil supporting the board at the point of cut.

- Efficient production of short orders.

- Modern controls, remote connection for assistance and diagnostics

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)