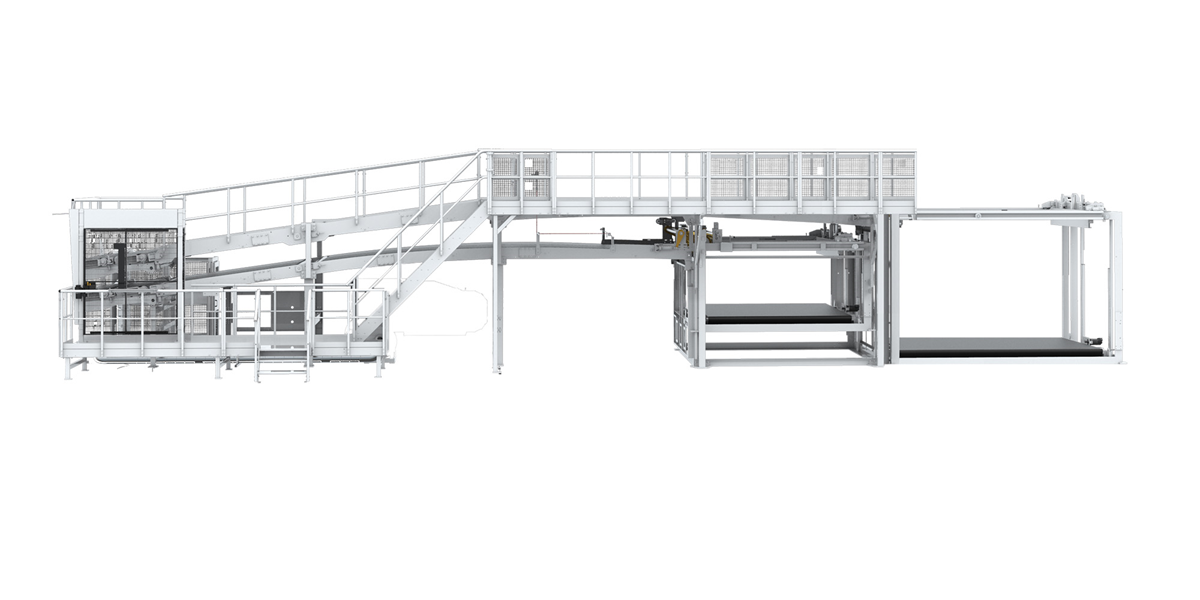

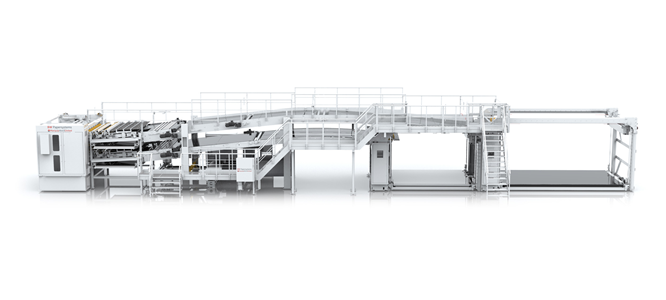

Corrugated Downstacker

Product Description

The BW Papersystems’ Downstackers provide outstanding stack quality and safe accessibility. Safety is optimal with stacker top-level access, lower-level access and infeed access.

Machines have flexibility on cam adjust infeed and a knife outfeed section with shingling brushes. It is a key component of any dry end upgrade and can be installed in conjunction with any OEM dry end components.

Other features of our advanced machinery include:

- Full-width V-Guide transport belts

- Continuous radius transport conveyor frame, preventing skewing of the shingle to the lift bay

- Patented speed switching allows clean load separation

- Reliable high-speed instant order change

- Exact sheet count

- Tail-based shingling

- Smooth acceleration and deceleration of the blue belt left bays

- High performance carbon fiber brushes

Downstacker Applications

BW Papersystems’ expert team designed the Downstacker to fit a variety of applications and needs. Our machine provides superior stack quality for corrugated cardboard and other boards. The sync vac system at the entry of the Downstacker features precise control of the corrugated sheets. The machine is designed to handle microflutes down to 0.06 in. (or 1.6 mm).

Custom Machine Configurations

Every application is different and BW Papersystems aims to meet every need. We provide custom catwalk configurations and conveyor lengths to ensure the machine fits with your existing production line. The Downstacker’s customization also ensures optimal operator use, safety and efficiency. Multi-order stacking and dual discharge options are available as well.

Product Features

The Downstacker incorporates many design features that allow for excellent stack quality.

- Custom design to match factory layout

- Patented speed switching allows clean load separation

- Exact sheet count

- Reliable high-speed instant order change, short cycle time and multiple orders

- Automatic shingling based on sheet dimensions

- Electric lift table control with short cycle times

- Uni-chain lift table conveyors

Custom Design

Customized bay lengths and bay heights. Engineered to match plant layout and needs for fastest operating speeds.

Belt Speed Switching & Exact Sheet Count

Patented control system provides clean load separation and delivers exact stack counts.

Instant Order Change, Minimized Cycle Times & Multiple Order Handling

Efficiently runs short orders and allows three orders per level at one time.

Automatic Shingling

Shingle overlap is determined by the sheet dimension and corrugator speed. The speed of the belts and the braking pressure of the carbon hold-down brushes are calculated to give the best performance. Straight and aligned shingle formation, smooth separation between loads and improved stack quality while avoiding crush.

Available Speeds

| Imperial | Metric |

|---|---|

| 820fpm | 250mpm |

| 1000fpm | 300mpm |

| 1150fpm | 350mpm |

| 1300fpm | 400mpm |

| 1500fpm | 460mpm |

Corrugated Downstacker

- Speed

- 250 mpm | 300 mpm | 350 mpm | 400 mpm | 460 mpm

- 820 fpm | 1000 fpm | 1150 fpm | 1300 fpm | 1500 fpm

Compare With

- Superior stack quality

- Minimized recovery time for short order efficiency

- Enhanced microflute capability

- Gap stop feature

Find Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)