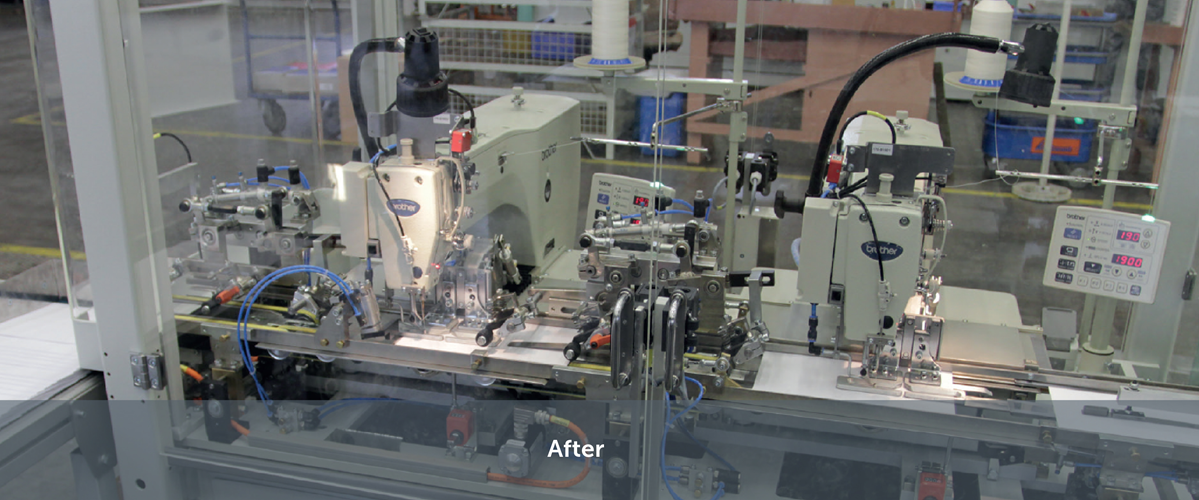

TIP P-1100 Interlock Stitching Module

Machine Model for Improvement

All Kugler-Womako Passport 1 Machines.Description of Improvement

Exact stitch length with 0 tolerance & shorter thread ends after thread cutting

Polycarbonate card won’t be moved during sewing process

Guaranteed spare parts supply

- Integrated control of upper thread

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)