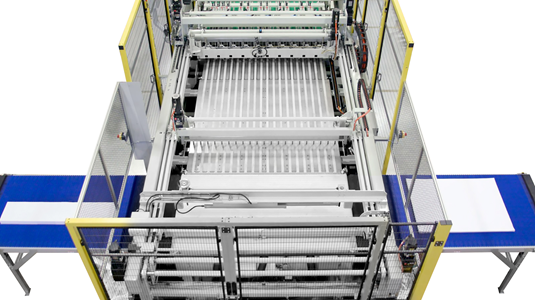

Questec RQS-V 1060 / 1650 Rotary Sheeter

Product Description

Learn more about our rotary sheeter and its unique sheet transport system below.

Product Features

The Questec RQS-V is a size flexible, high-speed sheeter with innovative sheet transport by air. It efficiently handles lightweight paper grades for patient information leaflets, package inserts, wet glue labels or scratch sensitive plastic films. A production speed of 400 m/min and extremely short start-up ramps make the RQS-V ideal for small batches and frequent order changes.

Precise Cut & Stack Quality

A clean, accurate cut with a cutting tolerance of ± 0,15 mm/1000 mm and a perfect stacking pattern due to gentle, safe pulling of the sheets onto the stack.

Various Sizes & Quick Change-Overs:

Compact, Ergonomic Design:

Easy Operation

With its job memory, few setting points and extreme short start-up time, the RQS-V needs little attention. One operator can run two RQS-V sheeters in parallel.

| RQS-V 106 ** | RQS-V 165 | |

|---|---|---|

| Max. Web Width | 1060 mm (42 in) | 1650 mm (65 in) |

| Min. Web Width | 400 mm (15.74 in) | 400 mm (15.74 in) |

| Sheet Length | min. 400 mm / 15.74 in max. 1060 mm / 42 in. | min. 400 mm / 15.74 in max. 1500 mm / 59 in. |

| Paper / Board Grammage | min. 60 gsm max. 190 gsm (optional: 250 gsm) | |

| Film Thickness | min. 50 μm max. 190 μm (optional: 250 μm) | |

| Max. Production Speed | 400 m/min. / 1300 ft/min.* | |

| Cut Accuracy | + / - 0,15 mm (0.006 in ) | |

| Pallet Height | 1500 mm | |

| Number of Webs | 1 | |

| Number of Pockets | 1-2 | 1-4 |

| Substrate | Paper, Board, Film, Wet Glue Labels, Specialties Papers | |

| Options Available | Unwind, Inline embossing, Web cleaner, Web inspection, Slitting, Cut-to-Register, Full-speed reject gate, Tab inserter, Sample taking device, Remote diagnostics | |

* dependent upon material characteristics & speed curve

** available in 2026

Questec RQS-V 1060 / 1650 Rotary Sheeter

Compare With

Highlights of the Questec RQS-V

- Speed: at 400 m/min. (1300 ft/min.), sheets are reliably cut and placed on the stack

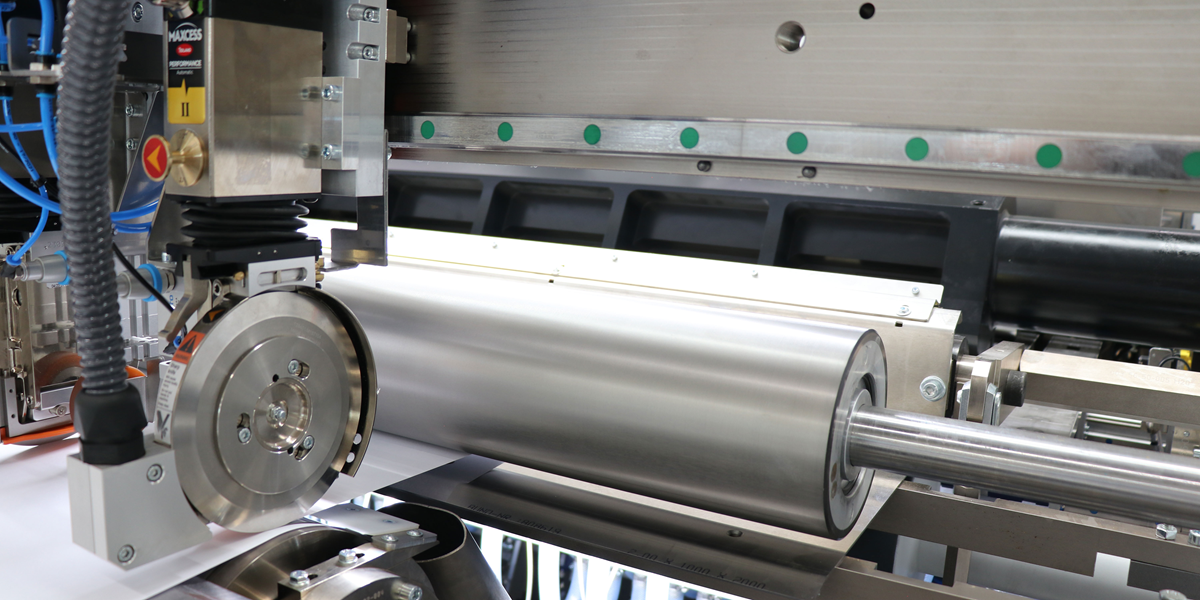

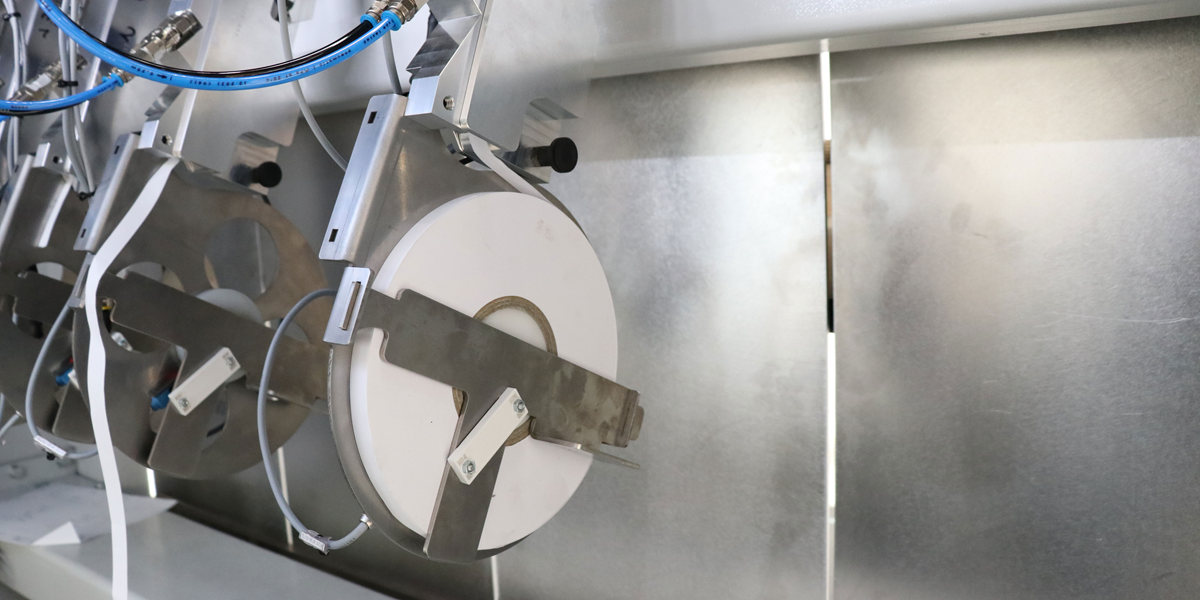

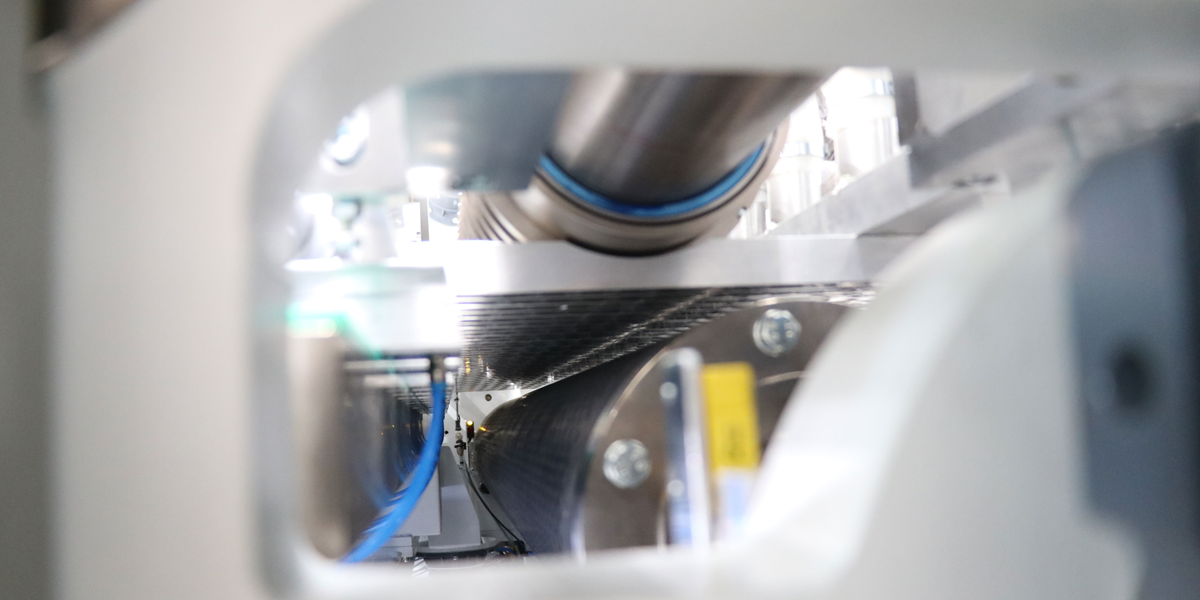

- Sheet transport by air: contactless «Air-Stream» transport without belts or rollers eliminates markings, turned-up corners (dog ears) or slipped sheets

- Precision: proven cross cutting technology with a dynamic drive allows for a clean, accurate cut with a cutting tolerance of ± 0,15 mm/1000 mm

- Quality: perfect stacking pattern due to gentle, safe pulling of the sheets onto the stack

- Compact & ergonomic: No platform and very small footprint of the main machine of less than 3 m (10 ft), thus well laid out and easy and safe to operate

- Reliable handling: thanks to «Air-Stream» the material is always safely transported, independent of web curvature, statics or surface condition

- Fast set-up times: extremely short start-up ramps thanks to fewer setting points plus job memory

- Virtually maintenance-free: a sheet transport without belts or rollers eliminates wear

Applications:

- Precision sheeting for manufacturers and converters of lightweight papers or plastic films, including materials with sensitive surfaces, e.g. in-mould labels, wet glue labels, pharmaceutical information leaflets or scratch-sensitive plastic films

- Inline integration with Offset, Gravure, Flexographic or Digital web-fed presses for commercial or specialty printers like product insert printers (PIL), even including embossing

Questec RQS-V - high speed, small batch sheeter at Drewsen, Germany

The Questec RQS-V is a size flexible, high-speed, small batch sheeter with innovative sheet transport by air. In this video you will see the machine in operation at our customer Drewsen Spezialpapiere, Lachendorf, Germany, as well as hear from its CEO, Dr. Matthias Rauhut, what he likes about this innovative sheeter and the partnership with BW Papersystems. The RQS-V efficiently handles lightweight paper grades for patient information leaflets, package inserts, wet glue labels, in-mould labels or scratch sensitive plastic films. A production speed of 400 m/min and extremely short start-up ramps make the RQS-V ideal for small batches and frequent order changes.

Watch VideoFind Your Machine

BW Papersystems offers a wide selection of paper industry equipment with industry-leading technology.

Learn more about the BW Papersystems equipment and products offered.

Works Well With

If you are looking for other machines in the process, here they are.

You Might Also Like

The machine or line you are looking at is great, here are some other models or individual line units.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)