The Shark – Our Game-Changer

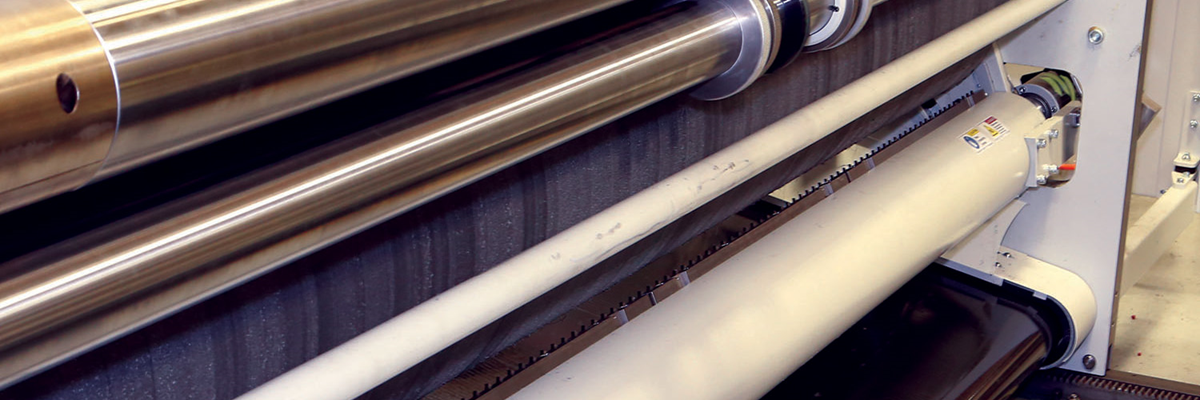

To combat this issue, MarquipWardUnited has developed The SHARK Anvil Blanket Trimmer, our new innovation which employs a hundred shark-like teeth that engage with the Anvil blanket. Powered by a motor and pneumatic pressure. The SHARK exploits the Anvil drum's natural lateral oscillation, trimming the blanket evenly and consistently. This reduces die wear, promotes cleaner die cuts, and of course, extends blanket life. The best part: the SHARK works while the machine is in operation which saves money and means no downtime.

The SHARK Anvil Blanket Trimmer system is available as a featured option on a new machine or as an upgrade to an existing machine. Please contact us for more information!

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)