Save time and money with the SHARK Anvil Trimmer for your Finishing Equipment

A common issue facing Finishing machinery is uneven wear on the Anvil urethane blanket. This can lead to costly production problems such as inconsistent sheet size and shortened blanket life. Frequent maintenance, repair, and even replacement of the Anvil blanket can result in extended machine downtime, potentially affecting an entire plant's operations.

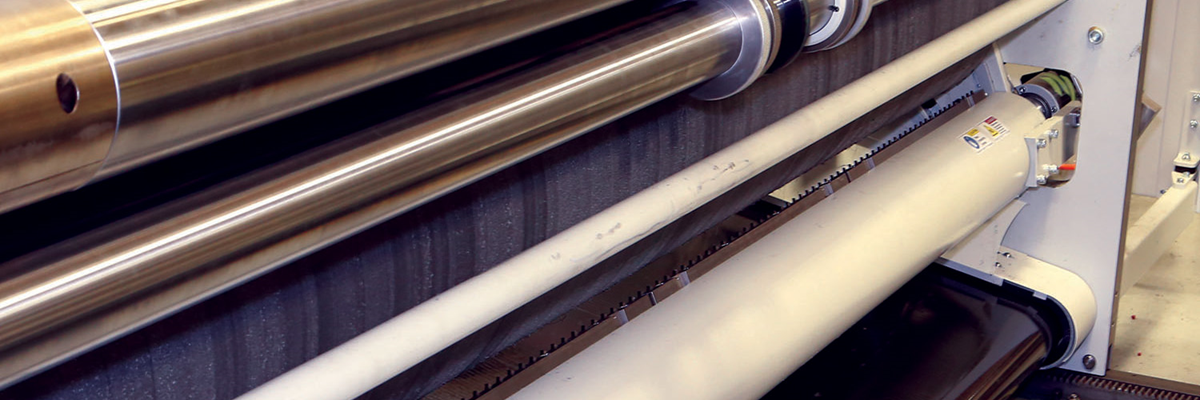

To combat this issue, BW Papersystems is proud to unveil our latest innovation. Exclusive to BW Papersystems, the SHARK Anvil Blanket Trimmer employs an assembly featuring approximately a hundred shark-like teeth that engage with the Anvil blanket. Powered by a motor and pneumatic pressure, the SHARK exploits the Anvil drum's natural lateral oscillation, trimming the blanket so that its wear remains even and consistent. This reduces die wear, promotes cleaner die cuts, and of course, extends blanket life.

The SHARK Anvil Blanket Trimmer system is available as a featured option on a new machine or as an upgrade to an existing machine. Please contact us for more information on this exciting new innovation!

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)