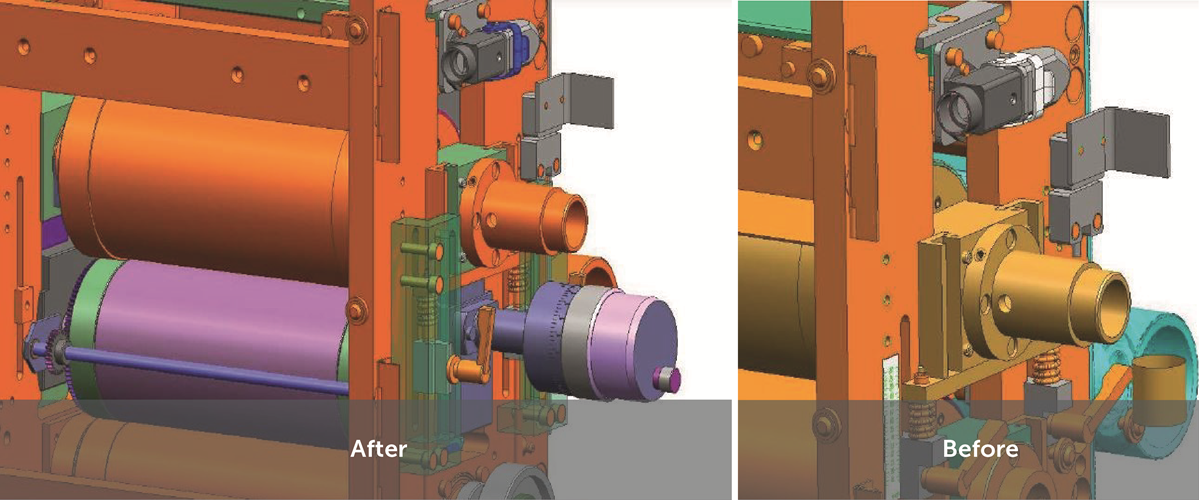

TIP R-5030 Replacement of Conventional Rotary Die Cutter by Variable Gap System

Machine Model for Improvement

All T165 RFID machines with a bearer ring rotary die cutting unit.Description of Improvement

This upgrade is part of the Technical Improvement Program (TIP) and it will incorporate the variable gap concept benefits into the die cutting station of the RFID converting process.

Benefits

- Adjustable, variable gap instead of a fixed gap

- Longer lifetime of the rotary die cutting tool, reduced wear

- Expanded product range with higher quality

- Backside punching still possible, now also adjustable

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)