TIP WEB-0405 Manual to Motorized Edge Roll Decurler Upgrade

Machine Model for Improvement

Folio-size sheeter type SHM 1400Description of Improvement

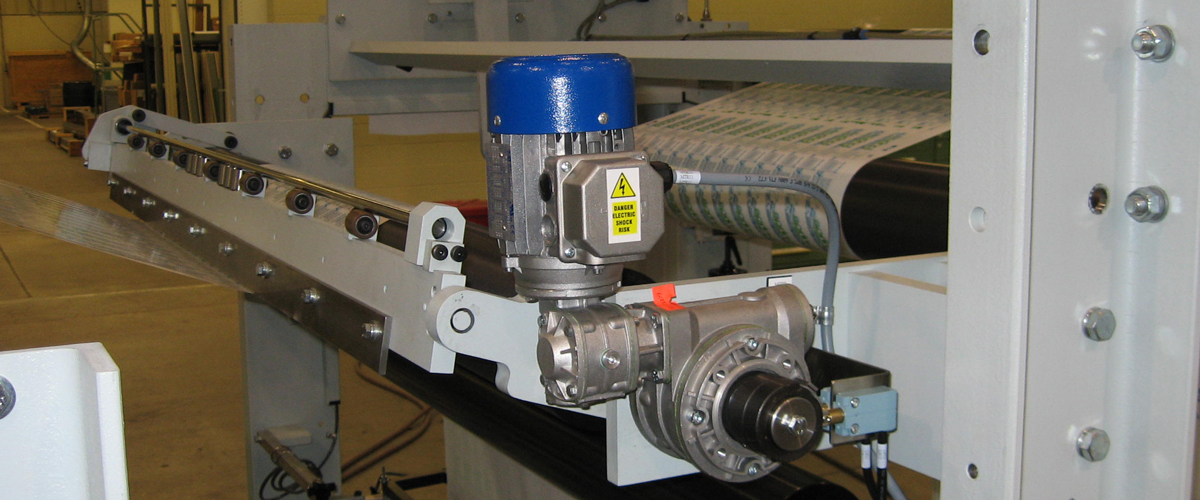

This upgrade is part of the Technical Improvement Program (TIP); it will convert the Manual Edge Roll Decurler to a motorized version. This is achieved by using a double reduction worm gearbox AC motor.

All the required electrical components, such as circuit breaker, overload protector, etc. are included in this upgrade. Newly supplied limit switches ensure protection against exceeding maximum movements in a given direction.

Benefits

- Provides easier operation under production

- Takes less time to make adjustments between roll changes

- Saves times for the operators so that they can focus on other areas of the machine

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)