TIP SHT-0406 Vacuum Overlap Conversion

Machine Model for Improvement

Folio-size sheeter type SHM 1400Description of Improvement

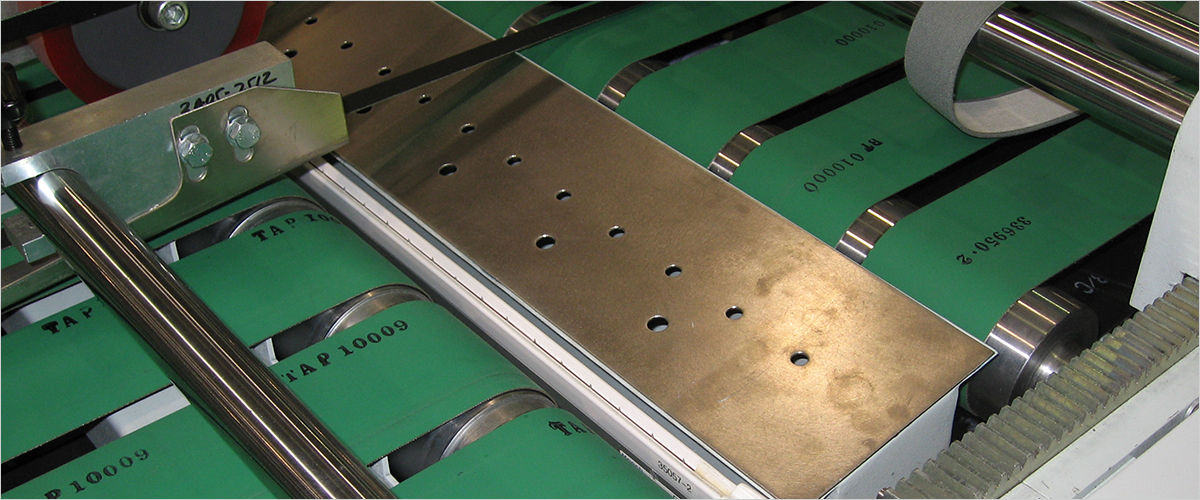

This upgrade is part of the Technical Improvement Program (TIP); it adds vacuum overlap to the machine. The new vacuum overlap box is located after the high speed tapes section. The vacuum box will pull the trailing edge of the ream as the sheets land on the low speed tapes.

This controlled handling of the sheets from high speed to low speed tapes allows the machine to handle sheets with more consistency and accuracy which results in increased speed and better looking stacks. The fan motor comes with a hose connector with four - 2 in ports are also included. The hoses then connect to the vacuum box. The manual adjustment handle allows the operators to adjust the amount of vacuum created to suit a given product.

Benefits

- Improves machine speed, reduces jams and markings

- Improves overlapping consistency and repeatability

- Improves stack quality

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)