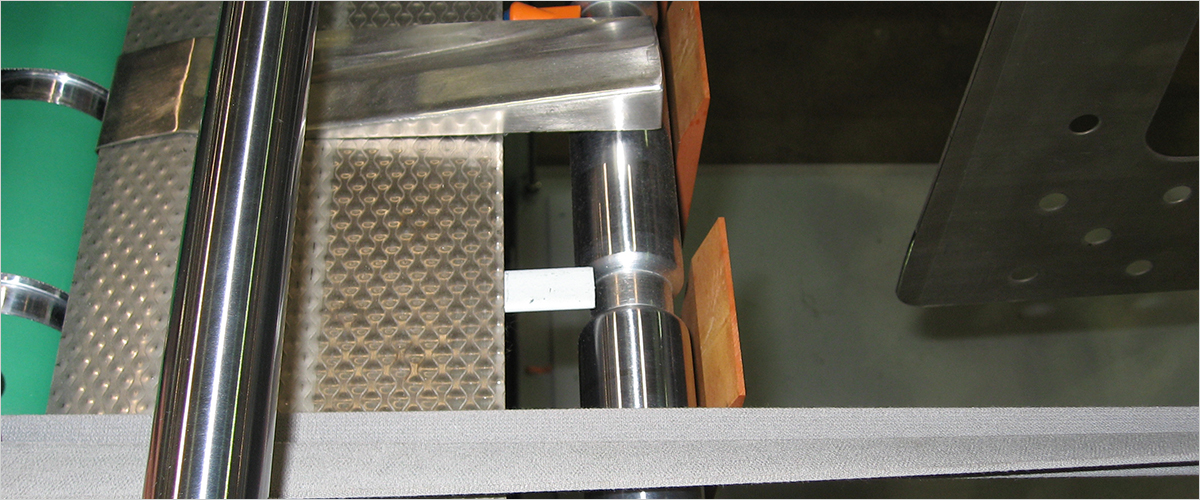

TIP SHT-0405 Grooved Kickoff Roller with Air Jets

Machine Model for Improvement

Folio-size sheeter type SHM 1400Description of Improvement

This upgrade is part of the Technical Improvement Program (TIP); it replaces the existing kickoff roller with a grooved kickoff roller. The grooves will allow positioning of the new air jets more strategically to get the most benefit out of them during sheet transfer into the stacker.

The angle of attack of the air jets will allow better sheet control during stacking of the sheets. Individual air flow controls will give the operator the flexibility to adjust each air jet independently for a given product.

Benefits

- Improved transition into the stacker results in improved stack quality

- Individual air flow adjustments for different products

- Ionized air jets can now be installed as a grooved roller and is a requirement for this

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)