TIP ROL-0404 Ultra-Sonic Tension Control for “SU” Rollstands

Machine Model for Improvement

Folio-size sheeter type SHM 1400Description of Improvement

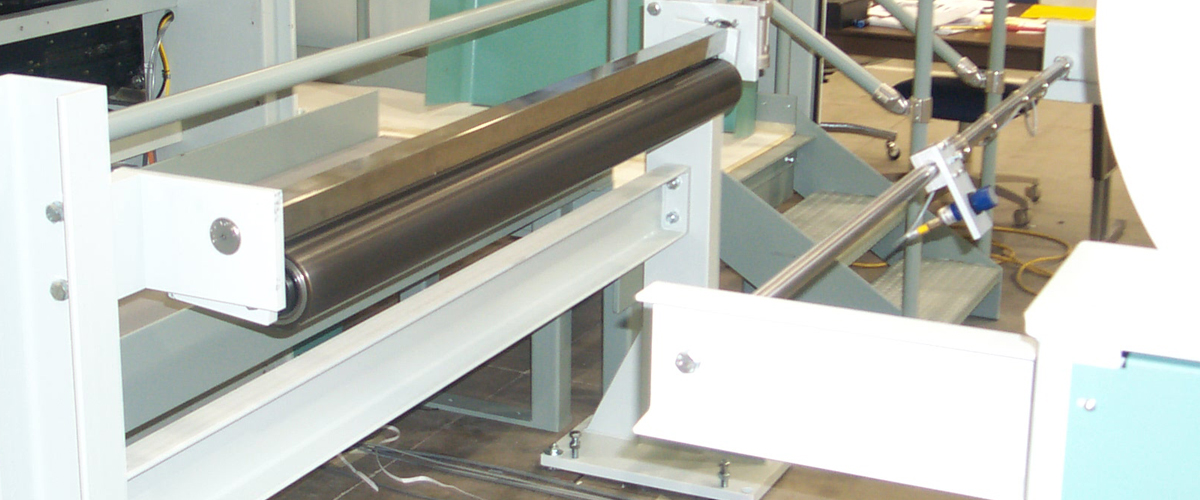

This upgrade is part of the Technical Improvement Program (TIP); it adds ultrasonic tension control to the SU roll stands. This conversion consists of adding a 30 mm proximity switch with a sensing range of 120 mm to 2000 mm.

The proximity switch is mounted to detect the distance from the roll to the switch. This distance is then converted to 0-10V DC analog output. As the roll diameter gets smaller, analog voltage increase. This information is then evaluated and the result is passed onto a newly supplied proportional air valve, which in turn adjusts the brake pressure. Coalescing filter ensures air quality to the proportional valve is clean.

Benefits

- Improved tension control

- Improved and consistent machine performance

- Easy setup and calibration

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)