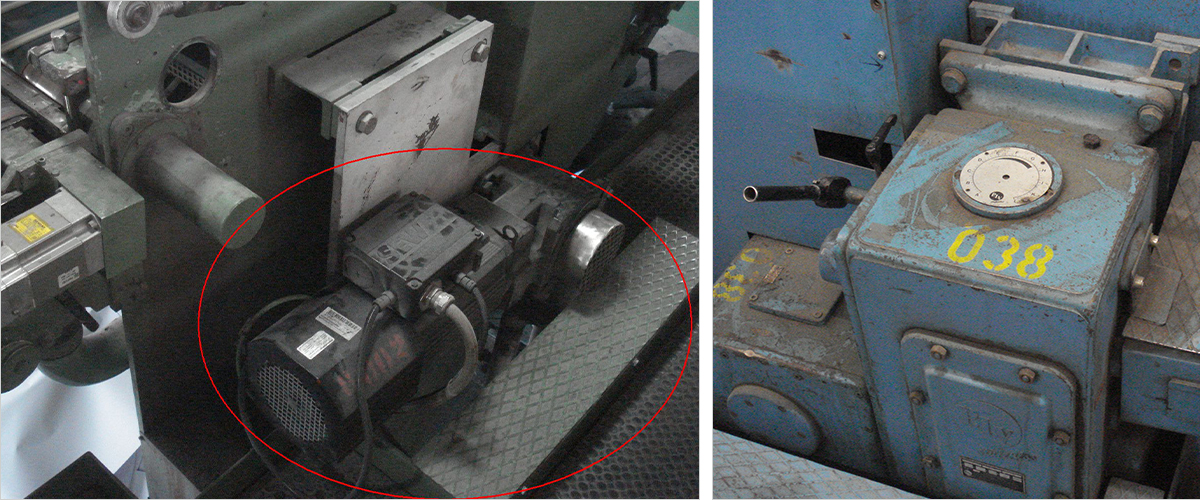

TIP F 2140 Replacement of the P.I.V. Gear box of the Belt Section to a Servo Motor

Machine Model for Improvement

All Jagenberg Sheeters with P.I.V. gear box

Description of Improvement

Over time and after years of intensive ‘around the clock’ production, the P.I.V. gear box wears out, subsequently breakdowns will occur.

This upgrade from the Technical Improvement Program (TIP) replaces the P.I.V. gear box of the outfeed belt section by a servo motor. The spare parts for the gear box are obsolete and no longer available.

The new servo motor is maintenance-free and increases the reliability of the sheeter. The production speed can be controlled more accurately compared to the P.I.V. gear box.

Benefits

- Spare parts availability and latest technology

- The new drive is maintenance-free

- Using standard components

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)