TIP F 1325A /1325B Replacement of the Obsolete Size Gearbox Combination & Main Motor

Machine Model for Improvement

All Jagenberg sheeters with obsolete P.I.V. gearbox (draglink system)

Description of Improvement

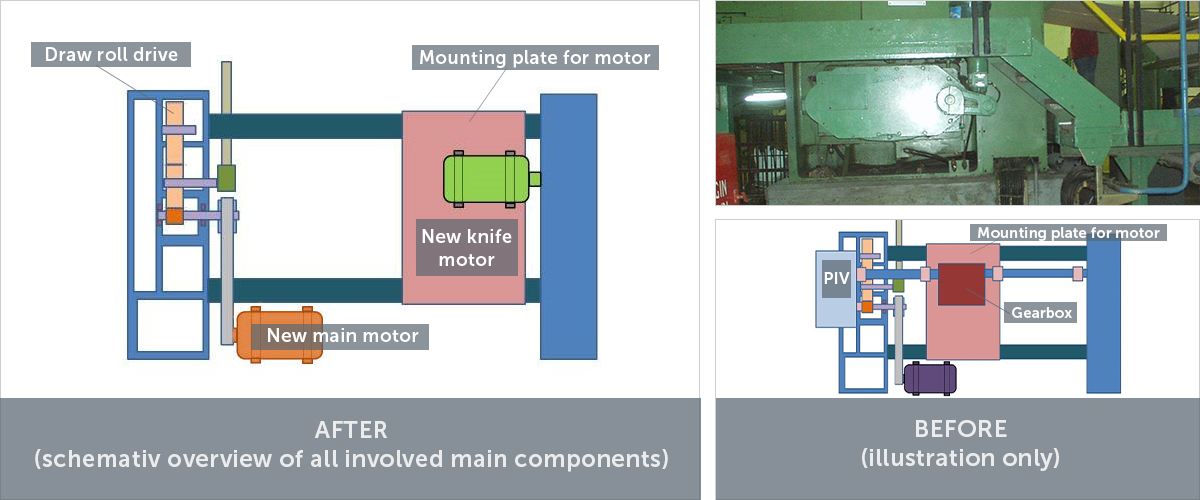

This TIP module is part of our Technical Improvement Program and replaces the existing obsolete PIV size gearbox combination (draglink system) and the existing main motor and drive.

The mechanical connection of the draglink to the main draw roll will physically disconnected. The existing drive shaft and the gearbox (manufactured by P.I.V.) will be removed.

A new AC knife motor (shown green in overview) will be installed and connected to the cross cutter drive shaft (draglink), driving the cross cutter. The AC knife motor will run in a ratio, dependent on the cut-off length, with the existing draw roll motor.

The currently installed DC main motor will be replaced by a new AC motor (highlighted orange in above overview).

The inverters for the new main motor and new knife motor work as a stand-alone system in a new additional switch cabinet. It will also hold a new operator touchscreen panel, allowing to display messages, notifications and the operator to input the desired cut-off length parameters.

TIP F 1325 A: New knife motor and new main motor are identical (benefit: only 1 motor type required as spare parts). The knife motor is larger as technically required.

- The existing P.I.V. gearbox is obsolete and no longer available

- Faster sheet length adjustment

- This TIP reduces the number of mechanical parts, new drive system is maintenance-free

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)