TIP CUT-0405 Heated Knife Roll Bearing Housings

Machine Model for Improvement

SHM 1400 SRDescription of Improvement

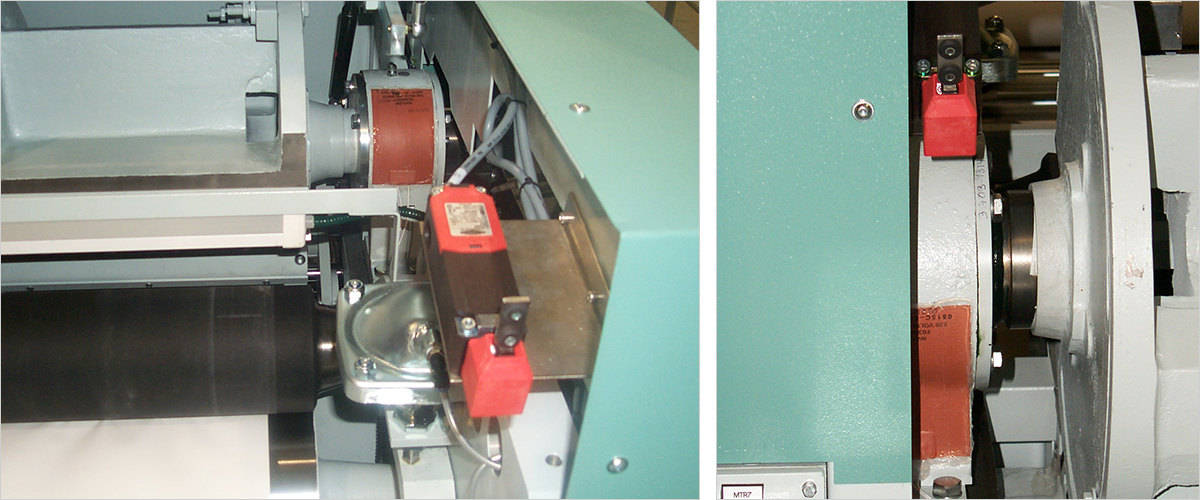

This upgrade is part of the Technical Improvement Program (TIP); it includes installation of four self-adhesive flexible heaters. Each knife roll bearing housing has two heaters.

These heaters are controlled and monitored by a temperature controller mounted on the main panel. The knife must not be rotated until the bearing temperatures have reached the preset values.

Benefits

- Significantly reduces knife clashes during cold startup

- More consistent operation and cut quality

- Improved knife life

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)