Benefits

- Increased divert reliability

- Remote teach splice sensors

- Minimized sheet waste

Machine Model for Improvement

eCon Sheeters

Description of Improvement

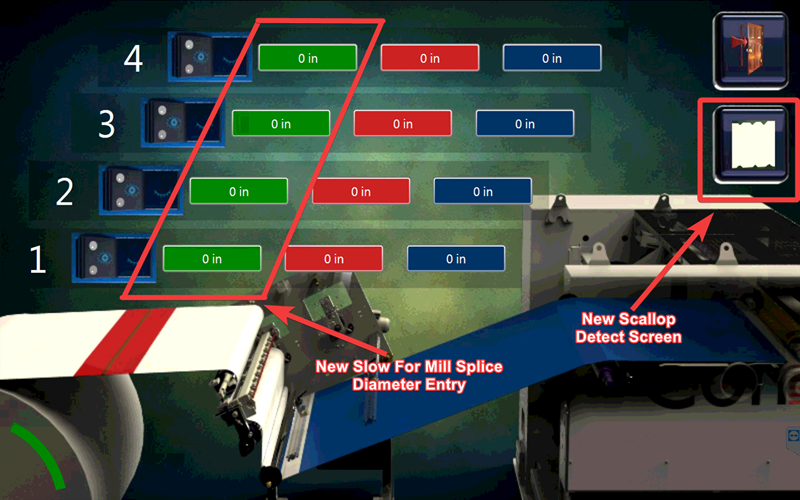

Upgrade to the current eCon mill splice system software with the following features:

When a new roll is loaded containing a mill splice in a known location, the operator can measure the diameter in the roll where the mill splice is located and enter it in the HMI. When the running roll nears the diameter where the splice is located, the sheeter will automatically slow down to a configurable speed, divert the mill splice, and speed back up to current order running speed, helping with divert reliability.

Remote teach functionality is added for the mill splice sensors for easier, more reliable sensor teaching. The teaching sequence will initiate automatically when the line starts and reaches or exceeds minimum speed or when the sensor input has been on for 2 seconds while the line is running.

The shingling belts will now stop when the machine is rejecting sheets. This functionality maintains a continuous shingle as the machine resumes from rejecting sheets, minimizing the number of sheets wasted.

Upgrade includes I/O module for teaching sensors, and wiring, along with any necessary engineering, install instructions, and document updates. waste.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)