TIP C 2215 Replacement of AMK KU Modules for Ream Reject Unit “Alfredomat”

Machine Model for Improvement

Description of Improvement

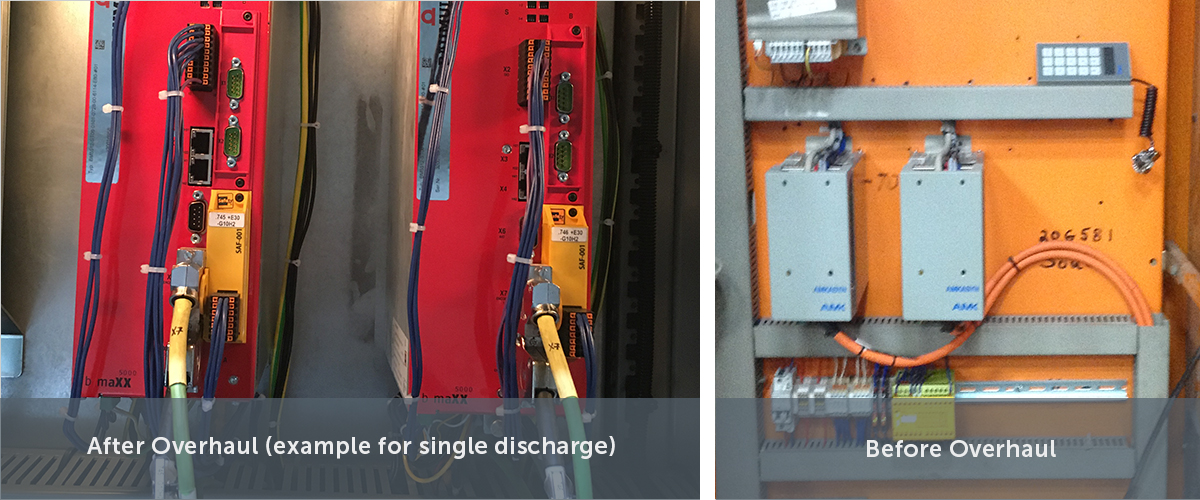

The existing AMK KU module series in the ream reject unit type “Alfredomat” is obsolete. This TIP replaces the existing AMK KU modules with a state-of-the-art servo drive system.

The functionality in the unit is restored with the original specification remaining unaltered. There is no change to the original ream reject speed.

Note: The installed AMK Motor will remain as it is. The replacement of the motor is optional and not included in the standard TIP scope.

As only the obsolete parts are replaced, this upgrade eliminates the risk and costs of unplanned downtime due to obsolescence with minimum investment.

Benefits

- Minimized risk of unscheduled downtimes due to obsolescence

- Minimum investment

- Spare parts availability

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)