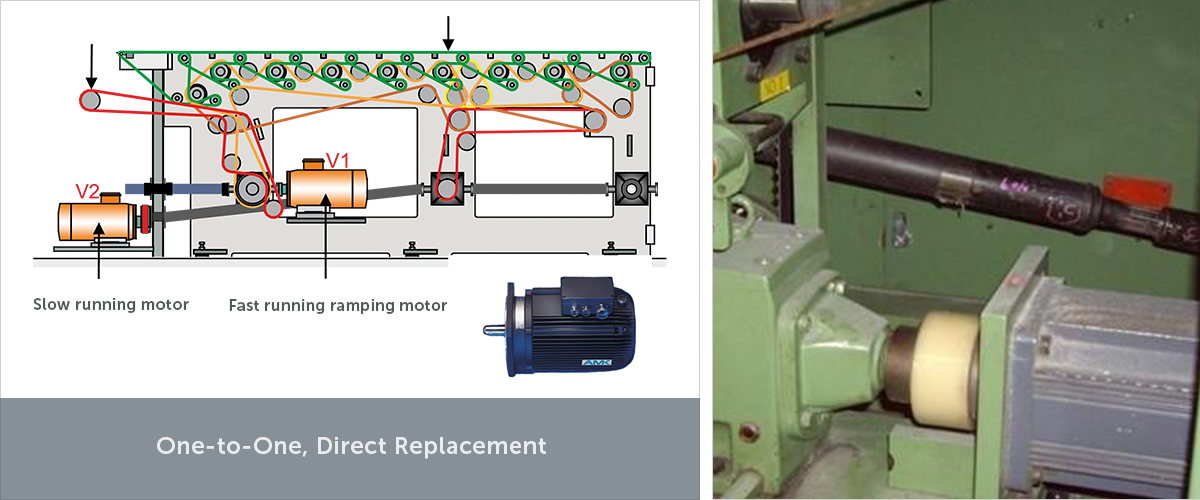

TIP C 2104 One-to-one replacement of obsolete V1 & V2 drives at the ream discharge

Machine Model for Improvement

Description of Improvement

All Contraves motors, controllers and HRU, PCU, ETU drive systems with encoders for the V1 and V2 drives at the ream discharge are obsolete. Any break down of these parts will cause an extensive and expensive, unplanned stop in production.

For a minimal investment, this upgrade replacing only obsolete parts greatly improves machine availability. The Contraves motors are exchanged for maintenance-free, state-of-the-art AMK AC servo drive motors and the Contraves drive components in the electrical cabinets are replaced by modern AMK drive components.

The use of just one type of motor and one type of controller reduces the number of spare parts needed. New cables to and from the controllers and motors are included in the scope of supply.

No mechanical parts are replaced or modified and the existing coupling will be kept. All original ream discharge functions remain unchanged and are transferred to the new AMK drive system.

Benefits

- Minimal investment: one-to-one replacement of obsolete drive parts only

- Improved machine availability

- Modern AMK system with maintenance-free AC motors

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)