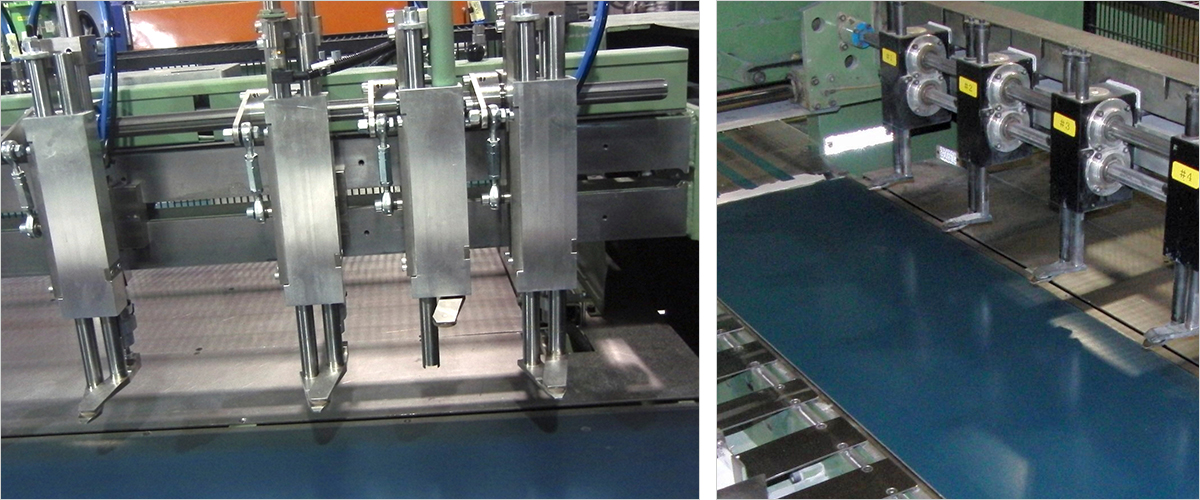

TIP C 2100 Modification of Grippers with Direct Pneumatic Control

Machine Model for Improvement

All E.C.H. Will cut-size sheeters SLK 440, SLK 470 and SLK 480

Description of Improvement

The existing mechanical gripper control cannot be selected directly by the operator, he needs to manually adjust the gripper and risks injuries due to the top gripper’s fixed spring load pressure.

speed dependent timing for the top and bott om grippers.

The exchange substantially reduces wear of parts in the gripper area, minimizing parts costs and maintenance effort. Less wear and tear also means less disturbances and improved overall reliability and availability of the sheeter.

The new pneumatic control system allows for a precise, adjustable pressure of the top gripper. This not only greatly increases the safety in that area but also is especially helpful when running pressure sensitive paper grades.

Benefits

- Reduced wear & tear at gripper significantly minimize maintenance cost and effort

- Easy, safe adjustment of gripper pressure with precise speed dependent timing of top and bottom grippers

- Increased reliability and availability of sheeter

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)