TIP C 1301 Modification of Main Drive

Machine Model for Improvement

Description of Improvement

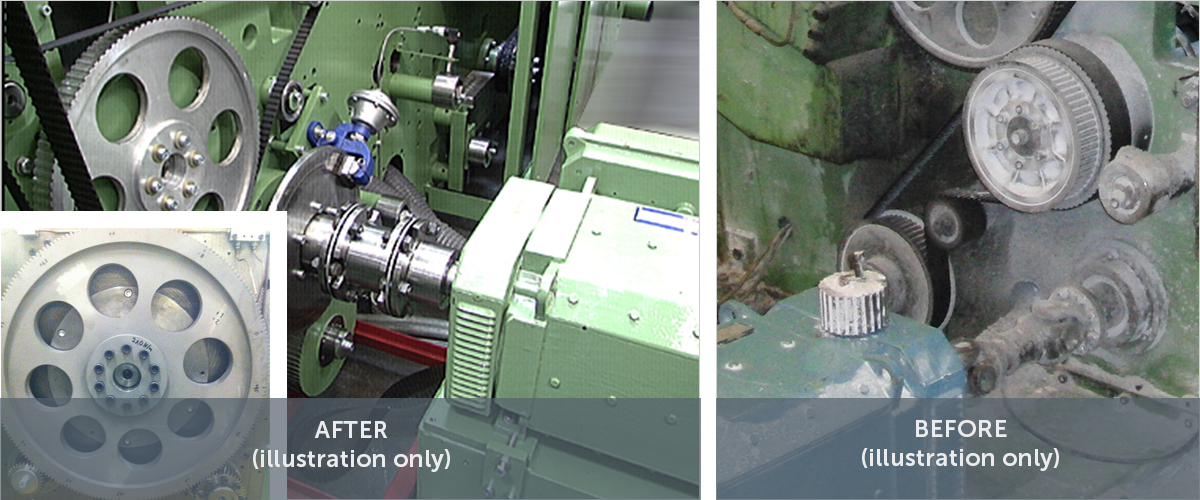

This improvement modifies and overhauls the main drive of the cut-size sheeter, greatly reducing noise emission and vibrations.

Wear and tear parts are reduced to a minimum: the universal joint shaft between main drive motor and machine is replaced by a coupling, and the long universal shaft underneath the main draw drum, connecting left and right side of the sheeter, is eliminated. In addition, the overall number of gears is reduced from six to three. Fewer spare parts mean less frequent and easier maintenance with lower costs.

By removing the universal joint shafts - a main cause for sheet length variations - sheet length accuracy is improved.

Benefits

- Fewer parts reduce maintenance cost

- Improved quality - main cause for sheet length variations is eliminated

- Smoother machine running with reduced noise emission

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)