TIP 130-0410 Transfer Pusher AC Drive

Machine Model for Improvement

Pemco packaging machine Model 135, 135HSDescription of Improvement

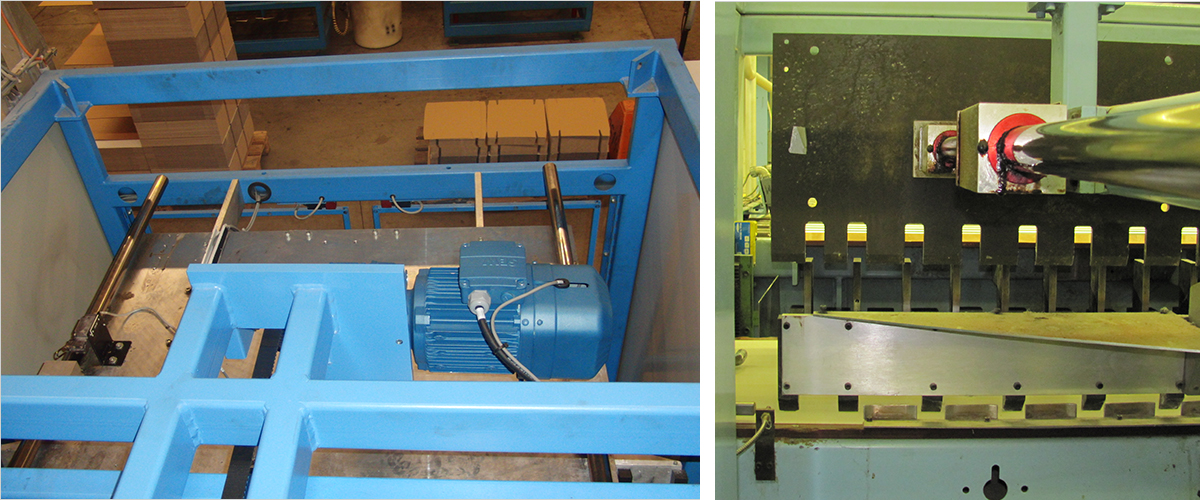

This upgrade is part of the Technical Improvement Program (TIP); it converts the transfer pusher from a hydraulic control to an electric motor.

This conversion consists of 1 ½ HP gear motor and 2HP 4 frequency drive. The drive is mounted into the existing enclosure (see prerequisites below) along with other enclosure devices such as relays, circuit breakers, potentiometers, etc.

This upgrade also comes with a new transfer pusher plate and support bracket for the pusher plate, tubular frame and mounting plate support for attaching the transfer pusher onto the frame. A timing pulley, shaft and a belt are provided to connect the motor to the transfer pusher. Torque limiter is also provided to protect the components in case of an overload condition.

Benefits

- Allows easy speed adjustment of the drive

- Precise and even movement of the transfer pusher elimination of transfer pusher hydraulics

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)