TIP 130-0401 Elevator Guide System

Machine Model for Improvement

Pemco packaging machine Model 135, 135HSDescription of Improvement

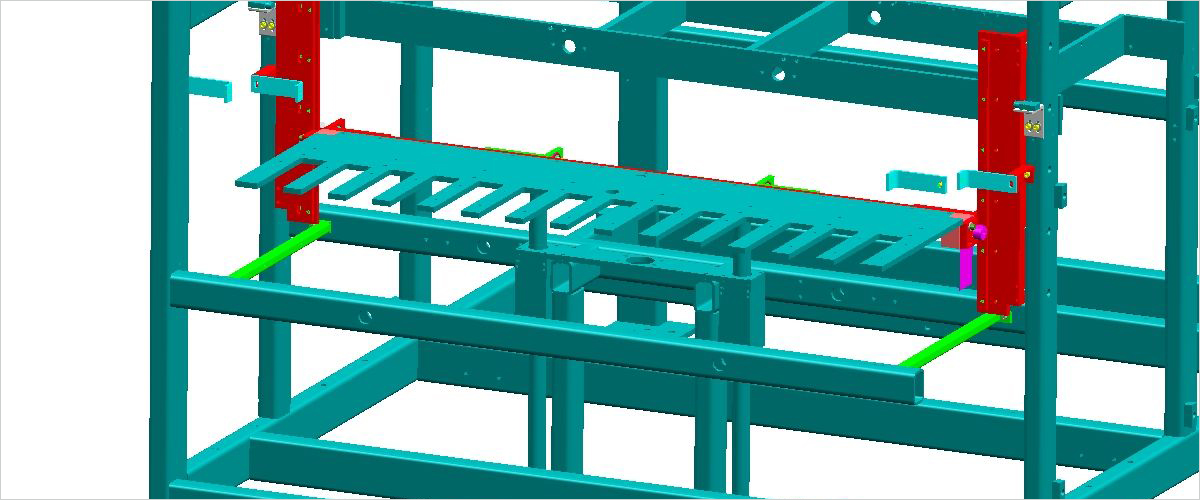

This upgrade is part of the Technical Improvement Program (TIP); the purpose is to improve the elevator guiding mechanism to allow more consistent stack handling by the elevator.

This is achieved by installing rack-and-pinion elevator guide system. This guide system also uses cam followers to ensure consistent elevator movement. This is very critical to ensure that the stack is parallel to the discharge surface.

A shaft with pinion gear mounted on each end rides on the gear rack allowing the elevator to move up and down. Cam followers riding on wear plates capture the shaft assembly in place. Additional side guards are also provided as part of this upgrade. This upgrade also includes a set of emitter and receiver photo eyes to replace the existing set.

These smaller sizes of eyes are necessary to work with the new elevator guide mechanism.

Benefits

- Reduces jams on the elevator

- More consistent stack appearance and handling into the case packer

- Reduces downtime and maintenance

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)