TIP 120-0406 End-Fold Laser Inspection System

Machine Model for Improvement

Pemco ream inspection machine Model 122 or 124Description of Improvement

The WillPemcoBielomatik engineered and designed system includes a laser inspection unit, PLC, and rejection capability on a Model 124/122 ream inspection unit. This system operates as a stand-alone unit, and can be added to any existing cut size line or new machine installation.

This system has the ability for quick order changeovers of varying wrapping materials, as well as ream sizes. The end fold laser inspection is not a replacement to the Model 124 ream inspection, rather a further device providing an additional inspection for optimal ream quality.

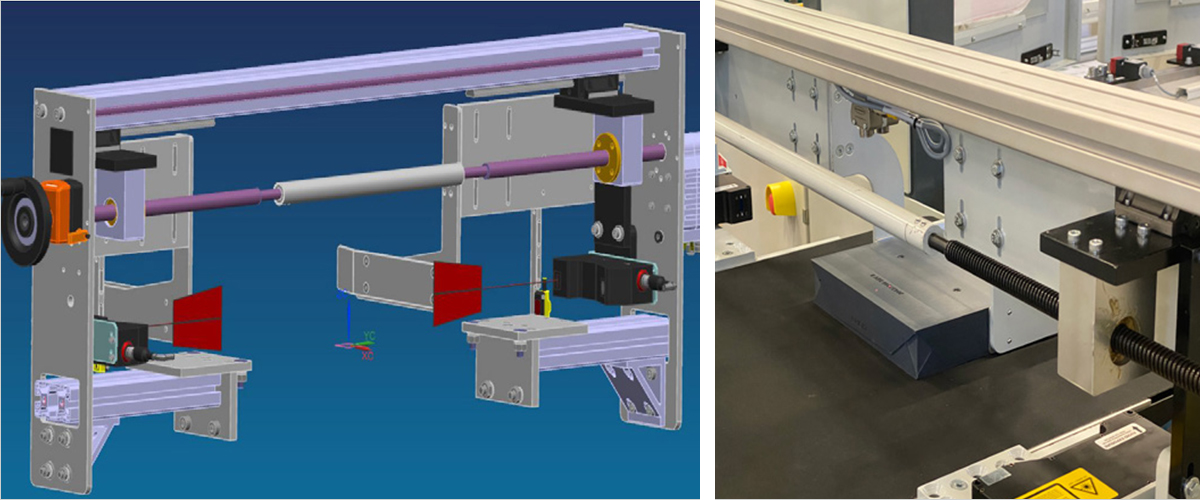

The system utilizes two (2) laser units for end fold inspection. The stand-alone inspection system will be located upstream from a Model 124/122 inspection system. Included in the standalone inspection system is a dedicated PLC to handle the proprietary inspection algorithms.

Also included will be a dedicated touch screen system for operator control. Operators will have the ability to set the inspection tolerance levels and system settings using the operator touch screen. By adjusting tolerance levels, the operator will have the ability to accept and reject reams with varying levels of quality based on customer preferences, wrapping materials, and other ream material factors.

The inspection system is designed to analyze all or part of each wrapped-ream end-fold. The inspection has the ability to determine poor quality or faulted reams based on ream-fold angles, double folds, and other wrapping qualities that create a visually-determined, poor quality ream (not based on printing or graphics on the wrapping material). Poor quality and non-conforming reams to the established tolerance will trigger rejection on the Model 124/122.

The inspection system will have the ability to be turned off without effecting operating conditions of other equipment in the production line. If the inspection system is enabled, the wrapping machine must be setup to provide proper, tightly wrapped reams to create acceptable end-folds on each ream-end. Poor or improper setup of the wrapping machine will result in an elevated probability of failed/ rejected reams as the fold variance will increase.

If the inspection system is turned off at any time, the production line must rely solely on the Model 124/122 inspection functionality for normal open flaps, protruding sheets, bottom girth, etc.

The End-Fold Laser Inspection System works with a variety of ream wrapping material.

Note: Unique or special ream wrapping material may require additional testing and evaluation. The system will have the ability to collect run-time statistics, collecting information about success and failure rates based on incremental units such as product runs, hours, days, etc.

Note: The End Fold Laser Inspection System does not include inspection for the following:

- Glue Temperature Detection

- Glue Presence Detection

- Girth Seal fault detection (this remains as part of Model 124 girth air blast)

- Folded Sheets inside of the ream (technology does not yet allow)

- Label inspection/detection/positioning

Benefits

- Quick change over, user friendly and adjustable tolerance levels of inspection

- Can inspect all or part of the reams

- Checks fold quality of reams

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)