TIP 030-0446 Gripper Separation

Machine Model for Improvement

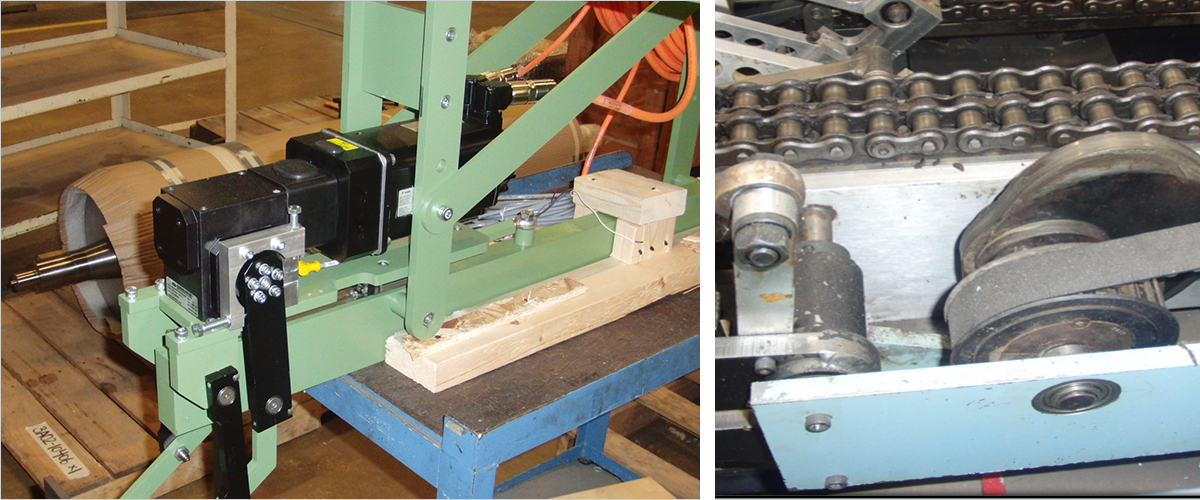

Pemco packaging machine Model 34, 34HS, 37HS.Description of Improvement

Benefits

- Removes the load from the overhead drive; extending life of spline shaft, broaches, chains, gears bearing, etc.

- Independent timing adjustments from touchscreen

- Eliminates complicated mechanical timing setup

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)