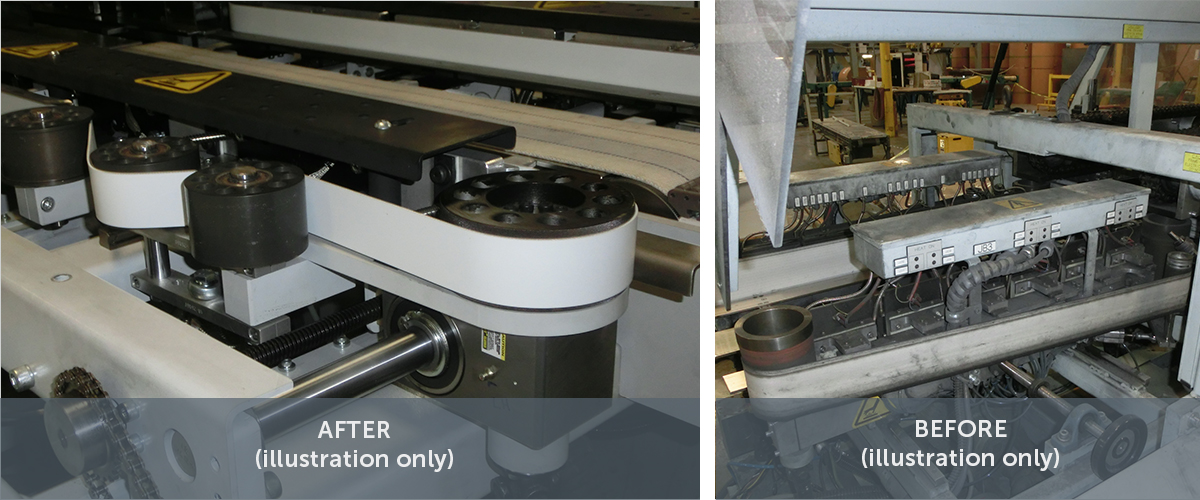

TIP 030-0440 Low Profile Poly End Seal

Machine Model for Improvement

Pemco packaging machine Model 32, 33, 34, 34HS, 37, 37HS, 39SDescription of Improvement

This upgrade is part of the Technical Improvement Program (TIP); it will replace the existing end seal assembly with a heated design that uses 40 mm wide belts. This new assembly will consist of the following:

- Side-to-Side Adjustment:

This section comprises of two sub-assemblies; one for right side and one for left side. Both sides move in and out using a single hand wheel. In this new design, these assemblies move on linear rails to ensure equal and parallel movement with respect to the ream and one another. - Belt Guide Assembly:

Belt guiding is simply done by means of capturing the belt in a formed plate. The length of this guide ensures proper guiding without additional electrical or mechanical guiding assemblies. - Heater Plates: Heater plates consist of a series of parts that make up a heater module. Each side has several independent plates per side. Each heater plate has its own heater and controller. These plates have the heater rods behind them in a horizontal orientation. Plates are easily replaceable from the top, and with quick disconnect electrical connectors. The plates will seal the end of the ream.

- Bottom Belt: A bottom belt will be utilized to help move the ream through the new end seal, rather than the existing design which squeezes the ream.

- Folding Section: Includes necessary parts with proprietary coating for poly operation.

- Electrical: Each heater plate will have its own thermostat and heater control. The heater controls will be done through Ethernet to a local touchscreen. The touchscreen will allow the operator to monitor and modify heat related parameters in each zone.

Benefits

- Longer belt and heater plate life, reduced maintenance and down time, linear rail design with accurate positioning

- User friendly with single heater element and controls per heater plate, touchscreen operator interface

- Even pressure applied on ream from each side of the end seal section, no springs

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)