TIP 030-0435 Vacuum Chambers with Center Slots

Machine Model for Improvement

Pemco packaging machine Model 34, 34HS, 37, 37HS, 38Description of Improvement

This upgrade is part of the Technical Improvement Program (TIP); it replaces the older vacuum chambers with current production type vacuum chambers.

The purpose of this upgrade is to improve the amount of vacuum for more consistent operation. The previously designed vacuum chambers consisted of a 1 ½ in (38 mm) hole that worked with dual-offset hole pattern vacuum belts.

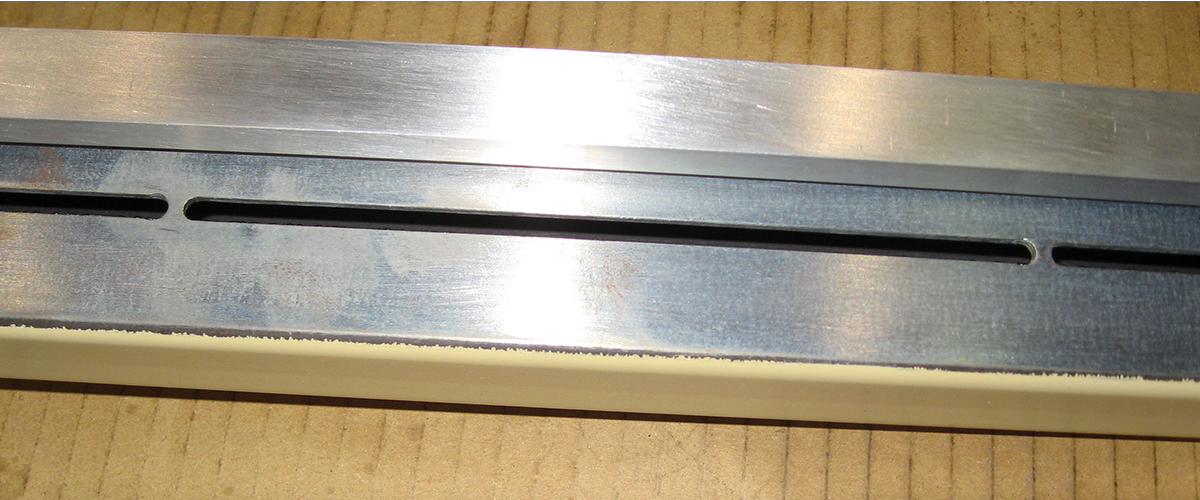

The new vacuum chambers come with eight (8) slots that are each 6 in (152,4 mm) long and 3/16 in (4,75 mm) wide. These chambers also require new style belts that have single in-line hole patterns. Vacuum belts must be glued during installation. This upgrade does not include heater press, glue, and other items required to glue the belts.

Benefits

- More vacuum for improved sheet control

- Accurate sheet placement

- Latest technology that is used on our current high speed machines

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)