TIP 030-0434 Dual Regenerative Vacuum Blowers

Machine Model for Improvement

Pemco packaging machine Model 34, 34HS, 35, 36 37, 37HS, 38Description of Improvement

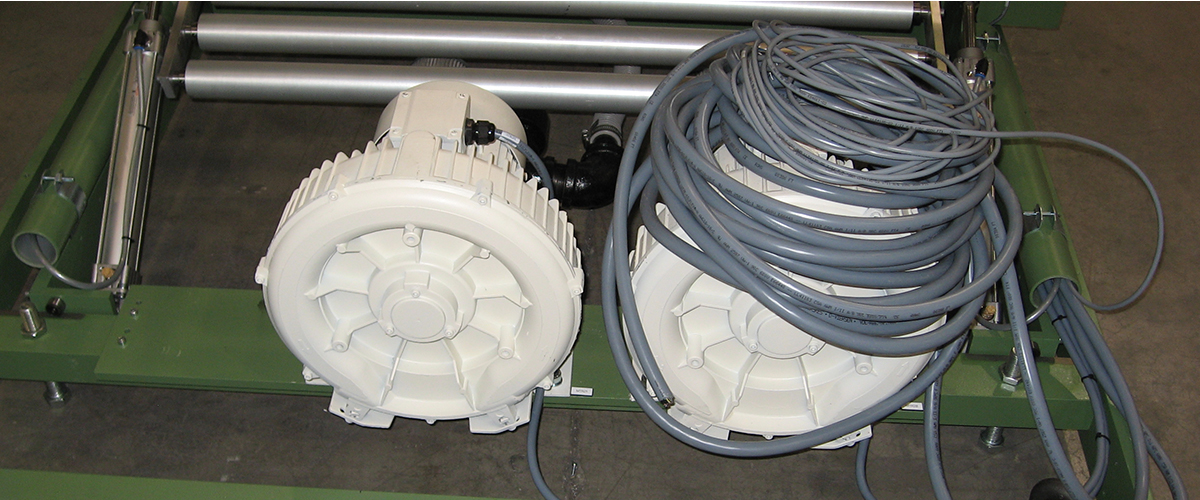

The purpose of this upgrade (which is part of the Technical Improvement Program TIP) is to install dual regenerative vacuum blowers instead of a single vacuum blower found on the wrappers.

Electrically, this upgrade consists of two 2HP motors, overloads, and motor starters. These motors are mounted on a newly supplied mounting plate. This plate will then be placed in the same location as the existing vacuum blower.

A newly designed vacuum belt manifold with discrete inputs and outputs, replaces the existing manifold. A three inch flexible hose is then routed from each blower motor to each vacuum chamber via the manifold. The blower motors are equipped with a intake filter/silencer and a manual ball valve to adjust the desired amount of vacuum independently to each vacuum chamber.

Benefits

- Eliminates bearings/shaft setup like on the single vacuum blowers

- No drive belt

- Allows individual vacuum control to each chamber for different products characteristics

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)