TIP 030-0424 Ream Squaring Mechanism

Machine Model for Improvement

Pemco packaging machine Model 34 and 37Description of Improvement

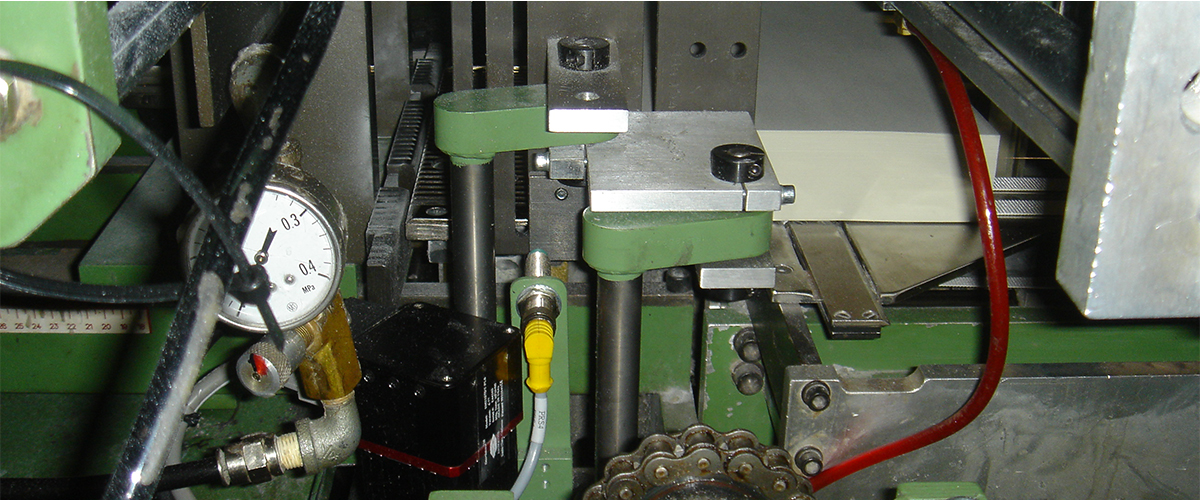

This upgrade is part of the Technical Improvement Program (TIP); it installs a ream squaring mechanism by the elevator. The squaring plates allow the ream to be precisely centered on the elevator prior into folding section.

This consistent centering also centers the ream between the tuckers, preventing jams or unnecessary widening of the machine. This design is similar to ream squaring mechanism found in the high-speed ream wrappers. The ream squaring mechanism is driven with a new mechanical linkage from the loader lever arm.

A hand wheel is included for size change and fine tuning for a given product. The existing loader lever is replaced with a new lever that has provision for connecting a rod and an arm that drives the pivot shaft. This upgrade also eliminates the infeed guides. As a result the bottom plates for the vertical infeed drive belts are replaced along with two new guide rails by the stop gate. Additionally, filler plate guards are used to protect the open area created by removing the longer infeed guides.

Benefits

- Reduces product damage and improves ream quality

- Eliminates infeed guides - no contact with product

- Precisely centers the ream on the elevator by forming a “box” between the loader fingers, back stop, and squaring plates

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)