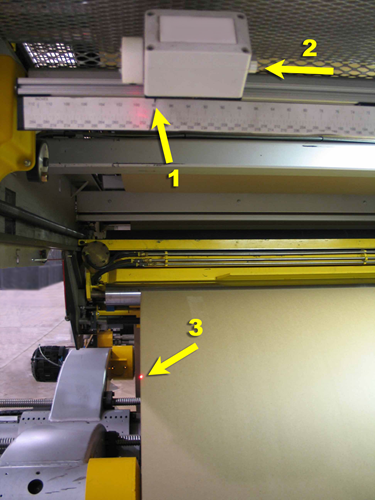

Splicer Laser Roll Aligner

Upgrade Applications

Applicable to all splicers (even non-MarquipWardUnited machines)Upgrade Description

The Laser Roll Aligner Upgrade is a complete package that will simplify the operator’s alignment of the new paper roll (new roll to be spliced in) to the running roll edge. The upgrade significantly reduces roll edge alignment errors when splicing in the new paper roll.

The Laser Roll Aligner allows easy, quick and very accurate roll positioning.

- The Laser is positioned to the desired cross machine position for that roll using a fixed scale reference for the roll width

- The operator presses a button to activate the alignment laser, which remains on a fixed amount of time (the amount of time is settable).

- The operator positions the paper roll edge to the laser light using the roll stand side shift controls.

Upgrade Benefits

- Eliminates roll-to-roll misalignment errors.

- Makes time for the operator to do other tasks.

- Significantly reduces edge alignment paper waste.

- Simplifies operator’s intervention for paper roll alignment

- Includes cross machine measuring rule for easy alignment to paper roll width.

- Battery operated laser for easy installation.

Technical Service

The BW Papersystems Service Department is a highly dedicated team of people committed to giving the best customer support in the industry. Trained technicians are available for emergency service, machine updates and maintenance.

Technicians are available throughout the world for fast response and quality service. Learn more about how our service technicians can help you.

.tmb-small.webp?Culture=en&sfvrsn=d9e817f_2)

.tmb-webp.webp?Culture=en&sfvrsn=6cca827f_4)